Braking a Motor

Two common basic methods used for braking a motor are DC injection braking and dynamic braking. We will look at both in detail, starting with electric braking.

1. DC Injection Braking

DC injection braking is a method of braking in which direct current (DC) is applied to the stationary windings of an AC motor after the AC voltage is removed. This is an efficient and effective method of braking most AC motors.

DC injection braking provides a quick and smooth braking action on all types of loads, including high- speed and high-inertia loads.

Recall that opposite magnetic poles attract and like magnetic poles repel. This principle, when applied to both AC and DC motors, is the reason why the motor shaft rotates.

In an AC induction motor, when the AC voltage is removed, the motor will coast to a standstill over a period of time, since there is no induced field to keep it rotating. Since the coasting time may be unacceptable, particularly in an emergency situation, electric braking can be used to provide a more immediate stop.

In turn, this constant magnetic field in the stator creates a magnetic field in the rotor. Since the magnetic field of the stator is not changing in polarity, it will attempt to stop the rotor when the magnetic fields are aligned (N to S and S to N).

DC injection motor braking demonstration (VIDEO)

The only thing that can keep the rotor from stopping with the first alignment is the rotational inertia of the load connected to the motor shaft. However, since the braking action of the stator is present at all times, the motor is braked quickly and smoothly to a standstill.

Since there are no parts that come in physical contact during braking, maintenance is kept to a minimum.

2. Dynamic Braking

Dynamic braking is another method for braking a motor. It is achieved by reconnecting a running motor to act as a generator immediately after it is turned off, rapidly stopping the motor. The generator action converts the mechanical energy of rotation to electrical energy that can be dissipated as heat in a resistor.

There must be access to the rotor windings in order to reconnect the motor to act as a generator. On a DC motor, access is accomplished through the brushes on the commutator.

In this circuit, the armature terminals of the DC motor are disconnected from the power supply and immediately connected across a resistor, which acts as a load. The smaller the resistance of the resistor, the greater the rate of energy dissipation and the faster the motor slows down.

The field windings of the DC motor are left connected to the power supply. The armature generates a voltage referred to as “counter electromotive force” (CEMF). This CEMF causes current to flow through the resistor and armature. The current causes heat to be dissipated in the resistor, removing energy from the system and slowing the motor rotation.

As a result, a motor cannot be braked to a complete stop using dynamic braking. Dynamic braking also cannot hold a load once it is stopped, because there is no more braking action.

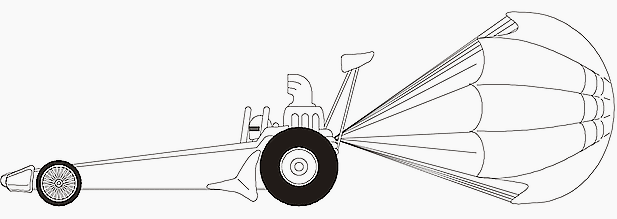

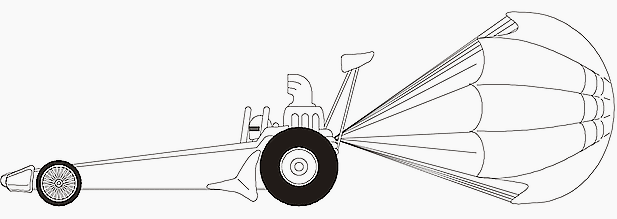

For this reason, electromechanical friction brakes are sometimes used along with dynamic braking in applications that require the load to be held, or in applications where a large heavy load is to be stopped. This is similar to using a parachute to slow a race car before applying the brakes.

Dynamic braking for AC motors can be handled with an adjustable frequency drive.

Reference // Basics of motors and motor control by Eaton

I have a DeWalt radial arm saw. When I release the switch the blade keeps rotating for a minute or so. The brake doesn’t seem to work properly. What should I look for in order to solve this problem?

I have a 3/4 HP bench grinder it no longer brakes on shut off. The wheels just run on for several minutes. How do we repair this?

My e-scooter BLDC don’t provide any braking system. i’d like to implement such a braking method on my own. Do you have any recommandation ?

Bello. Porque se llega a magnetizar la carcaza de un motor, y ala vez chisporrotean todas los carbones. Gracias.

Hey there, Greattings from Brazil,

I would like to give you guys a suggestion. It would be great if you guys write a article about “how to calculate a dynamic braking resistor.”

I look it up in the web and i found nothing about that.

Pleas help us!

i having some regarding the motors please give answers to my doubts…..

1. generally we are giving ac supply to dc motors how they will recieve dc supply

2. in plugging we are inter changing the armature or field terminals then how back emf is added to the supplied voltage

3.in dynamic braking how motor will acts as generator when resistor connected across it