Medium voltage distribution systems

Nowadays, system design engineers have a choice of many types of systems that may be used for a particular application. This discussion covers medium voltage distribution systems and their practical modifications. But first we will explain the basic primary / secondary and control / protection equipment of a medium voltage metal-clad drawout switchgear.

1. The basic design

1.1 Metal-Clad Switchgear Compartmentalization

Medium-voltage metal-clad switchgear equipment conforming to C37.20.2 is a compartmentalized design, wherein primary conductors are fully insulated for the rated maximum voltage of the assembly, and all major primary circuit components are isolated from each other by grounded metal barriers.

This type of construction minimizes the likelihood of arcing faults within the equipment and propagation of fault between the compartments containing major primary circuits.

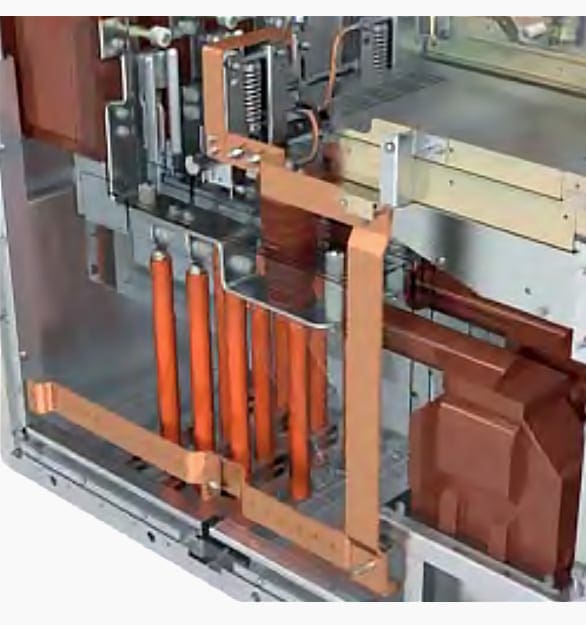

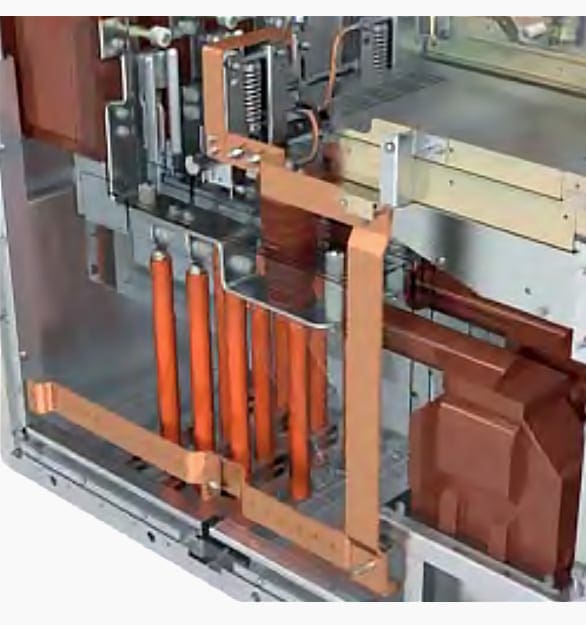

The bolted fault capability is verified by short-time and momentary short-circuit withstand current testing on complete switchgear, as well as by fault making (close and latch) testing on the switching devices as shown in Figure 1.

The short-time current withstand tests demonstrate electrical adequacy of busses and connections against physical damage while carrying the shortcircuit current for a given duration. The momentary current withstand tests demonstrate the mechanical adequacy of the structure, busses and connections to withstand electro-magnetic forces with no breakage of insulation.

It should be noted that design testing of standard metal-clad switchgear does not involve any internal arcing faults.

1.2 Primary and secondary equipment

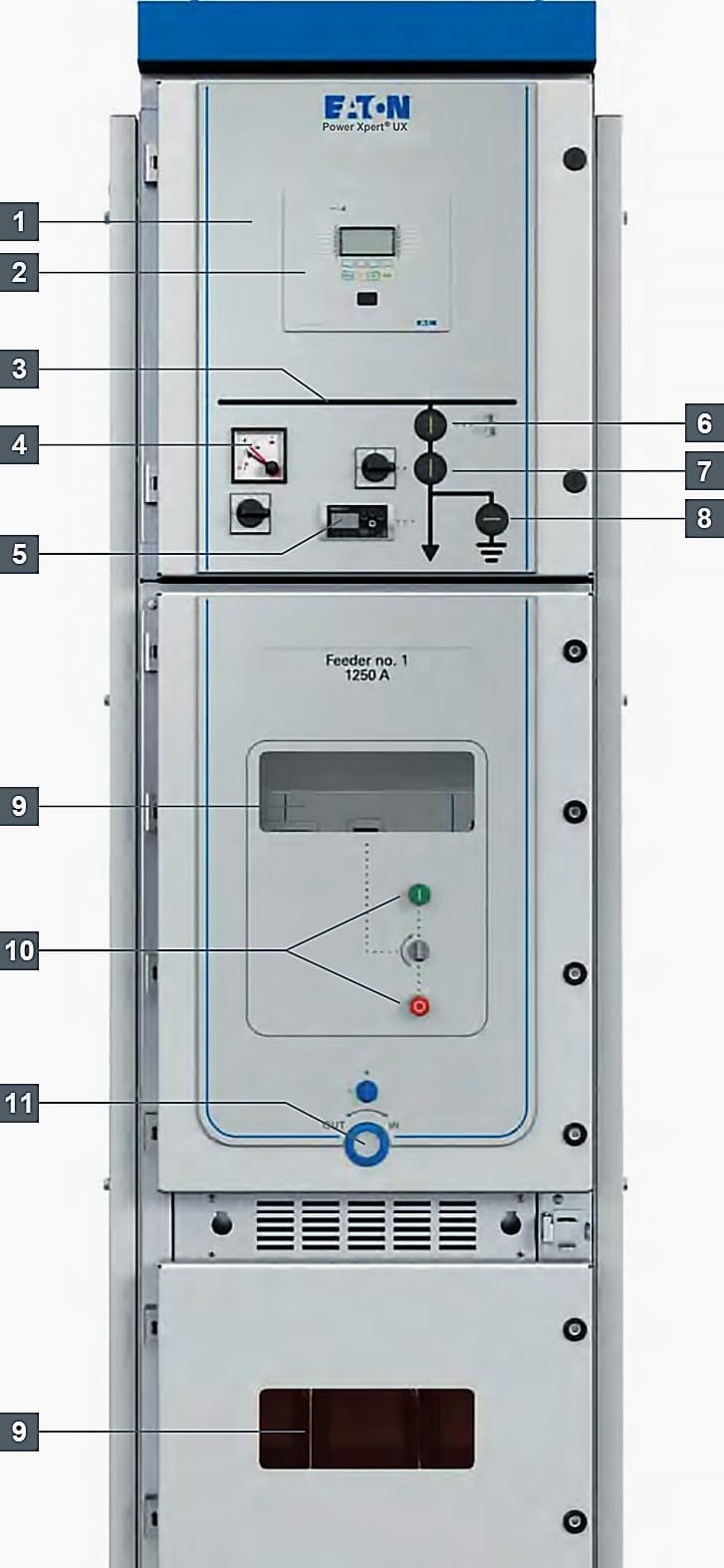

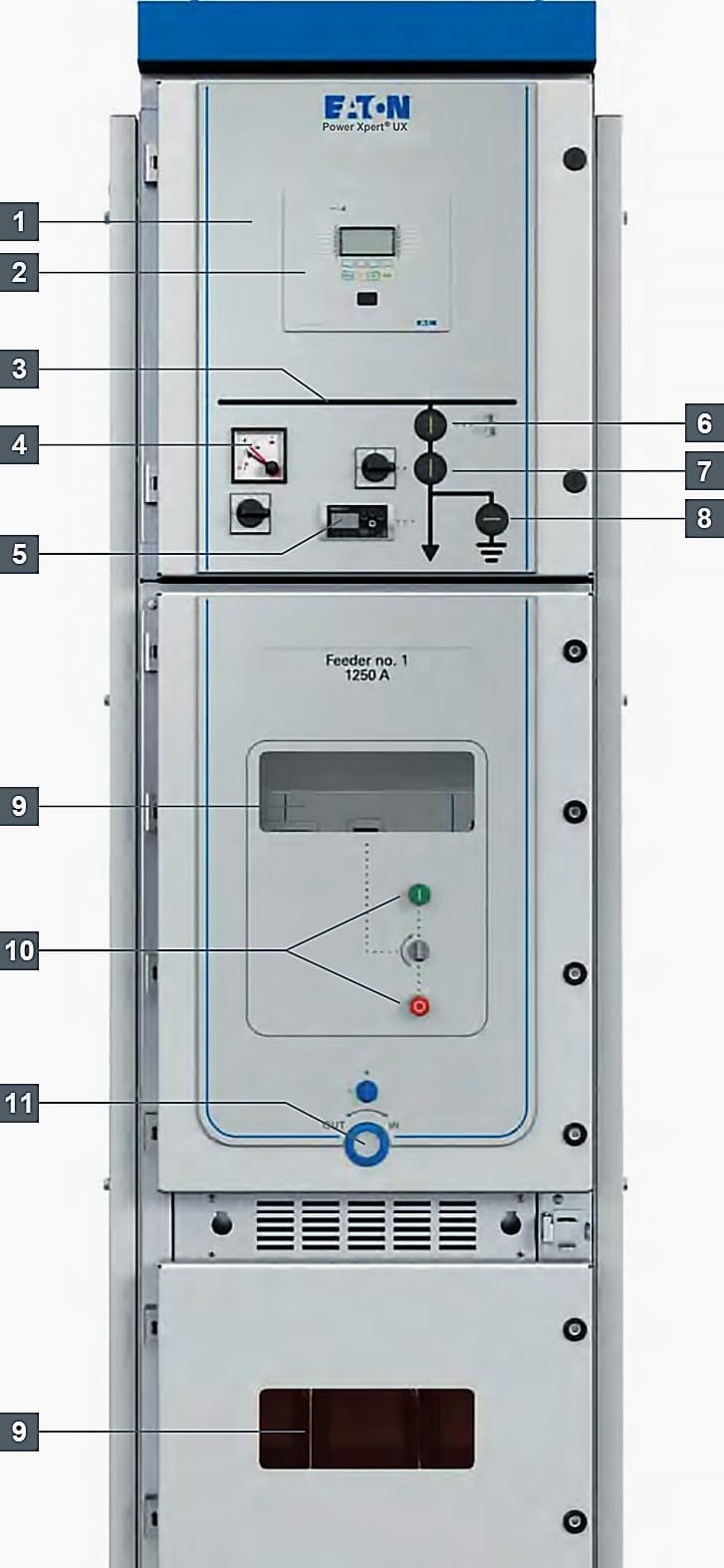

Let’s see what are the main parts of medium voltage switchgear. Please note that this example includes vacuum withdrawable circuit breaker as the main switching element and that there are other switchgears and manufacturers that produce the same switchgear, but with SF6 breaker.

1 – Arc chamber

The integral arc-chamber evacuates the gasses associated with an internal arc. Optional standard parts are available to extend the arc chamber; flanges and grilles are available to exhaust the gasses outside the switchgear room.

2 – Low voltage wire-way for inter panel wiring

A fully segregated metal wireway is mounted at the top of each switchgear panel that connects together to form a continuous low voltage wire-way that runs along the entire length of the switchgear.

3 – Low voltage compartment

The compartment is segregated with earthed metal partitions and has ample space for control and protection devices.

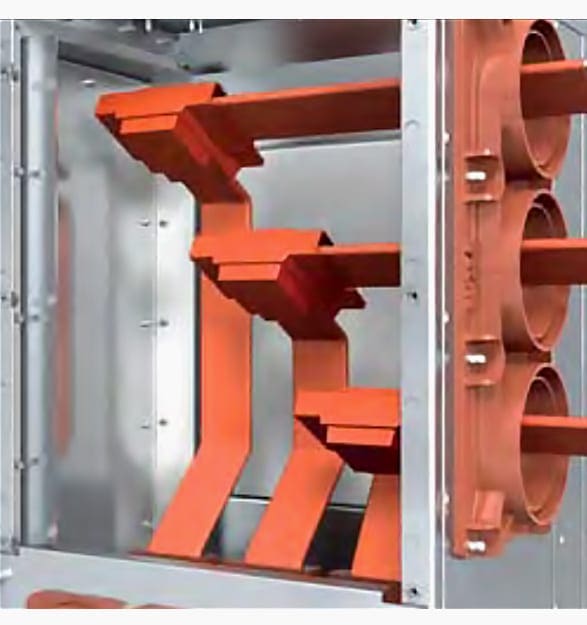

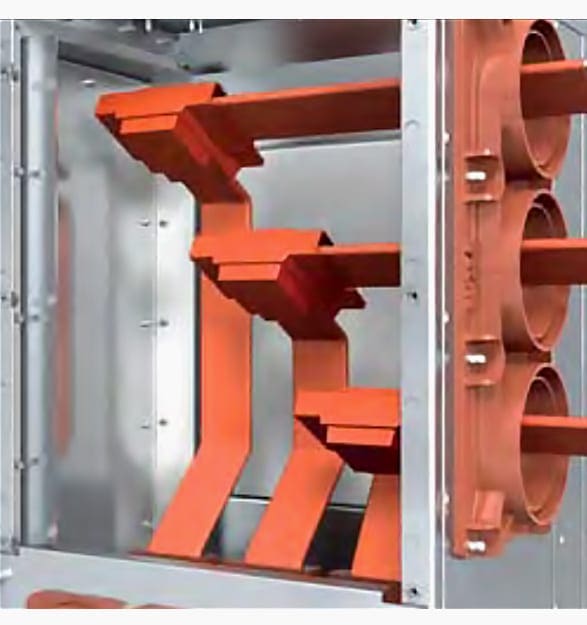

4 – Busbar compartment

Busbars are totally enclosed in their own earthed metal compartment which vents into the arc chamber. Fully insulated along their entire length, the busbars should be type tested for ratings up to 4000 A, 50 kA for 4 seconds.

Epoxy mouldings segregate switchgear sections.

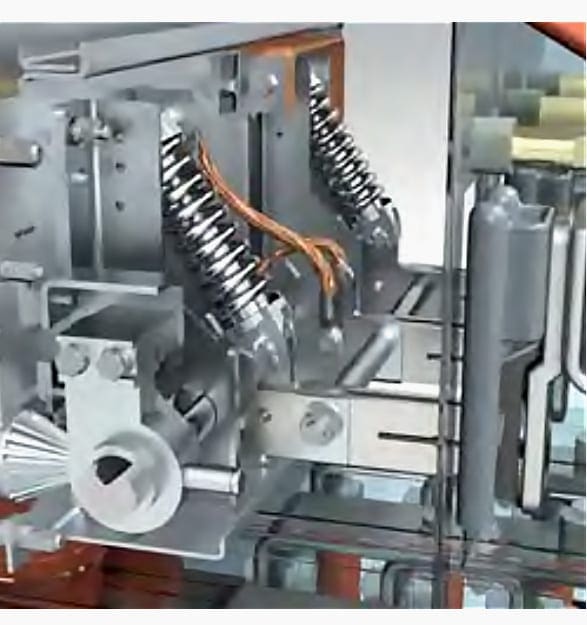

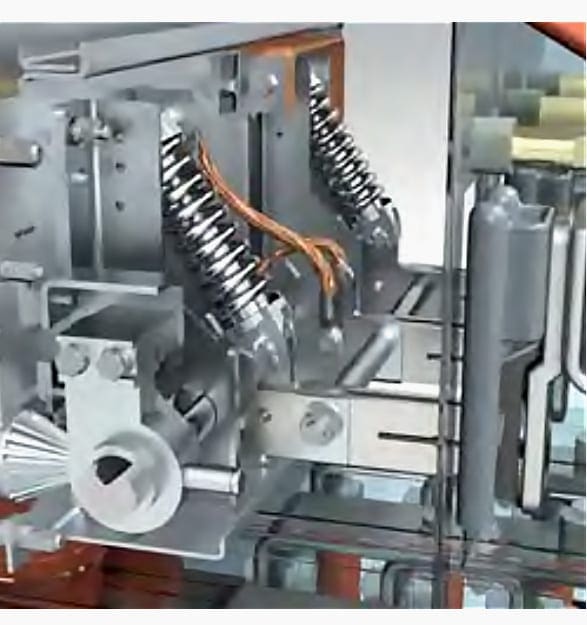

5 – Vacuum circuit breaker compartment

Fully segregated by earthed metal partitions, with its own pressure relief channel into the arc chamber, the compartment provides all the safety interlocking mechanisms required for safe and reliable operation of the vacuum circuit breaker.

The circuit breaker is mechanically interlocked with the compartment door so that the door cannot be opened until the circuit breaker is switched Off and racked out into the Test position.

6 – Automatic shutters

Individually operated automatic earthed metal shutters for both the Line (busbar) and Load (cable) connections can be padlocked in the closed position.

When the breaker is in Test or Disconnect positions the shutters automatically close to prevent accidental contact with any live parts.

7 – Circuit earth switch

The earth switch is operated from the front of the switchgear, with mechanical indicators to show the switch position. A window allows direct viewing of the earth switch position.

The circuit earth switch can be mechanically interlocked with the cable compartment door as an additional safety measure.

8 – Current transformers

Cast resin CTs are provided as standard in a wide range of ratings, with an option to use low voltage tape-wound CTs in the same location.

9 – Voltage transformers

The voltage transformers are fitted with withdrawable primary fuses to provide full isolation of the transformer. This arrangement is designed with maximum user safety in mind.

10 – Cable terminations

Ample cable termination provision is usually provided up to 9 single core cables per phase to enter the bottom of the switchgear and are terminated with compression lugs onto copper tails provided in the bottom of each panel.

11 – Earth bar

An earth bar system is provided making connections to the station earth easy and effective. The earth bar system has been fault tested and runs vertically and horizontally within each panel section and is connected to the earth switch, when provided.

1.3 Control and protection equipment

Every medium voltage switchgear has control, protection and signalization equipment installed. They are visible, easy to read and operate as they are divided into three sections: low voltage compartment, circuit breaker compartment and compartment for visual indication of the position of the circuit breaker.

Let’s see how they look like. Note that every MV switchgear on the market is pretty unique and that every described element could be placed somewhere else and/or look a bit different.

1 – Low voltage control and protection compartment

Clear to view panel with all controls and indications clearly visible and easy to operate.

2 – Protection relay

The brain of MV switchgear. Easy to spot. Usually have a display. Many manufacturers have a range of preferred relay options that can be fitted to the compartment door.

3 – Mimic diagram

Easy to understand mimic diagram of each circuit.

4 -Metering with phase selector switch

Option for an ammeter and phase selector switch. Option for voltmeter and phase selector switch.

5 – Voltage detection system (VDS)

Each circuit breaker panel can be equipped with three phase voltage detection system for voltage detection to IEC 61243-5. The VDS is driven from a capacitive divider fitted within the insulators connected to the cable connection and shows the operator if the connected cable is live.

6 – Circuit breaker position indicator

Breaker position indication shows the breaker in the Connected/Service or Disconnected/Test position.

7 – Electrical operation with circuit breaker status indicator

- Breaker Open/Closed status indicator.

- Breaker Open/Closed command switch.

- LED indication of spring charge mechanism “Charged” status

8 – Earth switch indicator

LED indication of earth switch Open/Closed status.

9 – Viewing windows

The circuit breaker compartment door viewing window provides visual indication of the position of the circuit breaker indicating:

- The status of the breaker

- The status of the spring-charged mechanism

10 – Manual circuit breaker operation

Circuit breaker Open and Close buttons.

11 – Circuit breaker racking mechanism

Circuit breaker racking In/Out mechanism.

2. Medium voltage system configurations

Medium voltage system is mainly used in power plant, substation, industrial and mining factories, as well as high-rise buildings, for power reception and power distribution, with functions of controlling, protecting and detecting electric circuits.

The medium voltage system configurations shown are based on using metal-clad drawout switchgear explained above.

Note that the service continuity required from electrical systems makes the use of single-source systems impractical because outage of the utility results in total outage of the switchgear, which is absolutely not acceptable.

That’s why we will introduce few other basic MV design configurations.

2.1 Single Bus Configuration

The sources (utility and/or one/more generators) are connected to a single bus. All feeders are connected to the same bus. This configuration is the simplest system.

However, outage of the utility results in total outage.

Any future addition of breaker sections to the bus will require a shutdown of the bus, because there is no tie breaker.

2.2 Single Bus with Two Sources from the Utility

Same as the single bus, except that two utility sources are available. This system is operated normally with the main breaker to one source open.

Upon loss of the normal service, the transfer to the standby normally open (NO) breaker can be automatic or manual. Automatic transfer is preferred for rapid service restoration especially in unattended stations.

Retransfer to the “Normal” can be closed transition subject to the approval of the utility. Closed transition momentarily (5–10 cycles) parallels both utility sources.

Caution!

When both sources are paralleled, the fault current available on the load side of the main device is the sum of the available fault current from each source plus the motor fault contribution.

It is recommended that the short-circuit ratings of the bus, feeder breakers and all load side equipment are rated for the increased available fault current.

If the utility requires open transfer, the disconnection of motors from the bus must be ensured by means of suitable time delay on reclosing as well as supervision of the bus voltage and its phase with respect to the incoming source voltage.

This busing scheme does not preclude the use of cogeneration, but requires the use of sophisticated automatic synchronizing and synchronism checking controls, in addition to the previously mentioned load shedding, automatic frequency and voltage controls.

This configuration is more expensive than the scheme shown in Figure 14 above (single bus scheme) but service restoration is quicker. Again, a utility outage results in total outage to the load until transfer occurs.

Extension of the bus or adding breakers requires a shutdown of the bus.[/warning_bus]If paralleling sources, reverse current, reverse power and other appropriate relaying protection should be added as requested by the utility.

2.3 Multiple Sources with Tie Breaker

This configuration is similar to the configuration shown in Figure 15 above (Single Bus with Two-Sources Configuration). It differs significantly in that both utility sources normally carry the loads and also by the incorporation of a normally open tie breaker.

The statements made for the retransfer of the configuration shown in Figure 15 apply to this scheme also.

If looped or primary selective distribution system for the loads is used, the buses can be extended without a shutdown by closing the tie breaker and transferring the loads to the other bus.

See the caution for Figure 15, Figure 16 and Figure 17.

In Figure 4, closing of the tie breaker following the opening of a main breaker can be manual or automatic. However, because a bus can be fed through two tie breakers, the control scheme should be designed to make the selection.

The third tie breaker allows any bus to be fed from any utility source.

Caution for Figure 15, Figure 16 and Figure 17

If continuous paralleling of sources is planned, reverse current, reverse power and other appropriate relaying protection should be added. When both sources are paralleled for any amount of time, the fault current available on the load side of the main device is the sum of the available fault current from each source plus the motor fault contribution.

It is required that bus bracing, feeder breakers and all load side equipment is rated for the increased available fault current.

2.4 Conclusion

The medium-voltage system configurations shown are based on using metal-clad drawout switchgear. The service continuity required from electrical systems makes the use of single-source systems impractical.

In the design of a modern medium-voltage system, the engineer should:

- Design a system as simple as possible.

- Limit an outage to as small a portion of the system as possible.

- Provide means for expanding the system without major shutdowns.

- Design a protective relaying system so that only the faulted part is removed from service, and damage to it is minimized consistent with selectivity.

- Specify and apply all equipment within its published ratings and national standards pertaining to the equipment and its installation.

Sources:

- Power system design basics – Eaton

- 12kV Power Xpert UX Catalog – Eaton

I’ve been following EEP for quite a long time now and its topics are always informative and helpful. Another great thing about the portal is that it provides countless technical information from general to detailed for free. People behind EEP deserve high appreciation. Thank you EEP! Please keep it up. :)

I have seen most of you explanation which is very detailed. my question is what is the proceedure used in taking the values or what procedure do you use to take mesurment from a substion?

Hi Andy, I really do not understand what do you mean by this. You can read the whole article, from top to bottom, do you? It’s free for reading, and I don’t see where you find that EEP asks for the payment.

If you mean creating PDFs, then yes, this feature is available only for premium members, and it applies to all technical articles on the EEP. I don’t see the problem with this. I agree that you could find much information on many websites, and nobody’s stopping you from searching elsewhere.

How do you mean EEP survives in these challenging times? By sharing everything for free? And, btw, EEP is sharing a lot for free content of any charge.

Ver nice portal Ok

can you please send me the above book

Excellent, information, and technical expertise, Thank you for share

Really very fantastic and conceptual.alot of knowledge I have got from ur portal

I am in T&D relating to Electricity Supply Systems. This material, particularly the photos and schematics are excellent resources for training purposes, Kevin

Another important issue to mention is that the Eaton UX Switchgear, have the possibility have an internal arc chamber extinction. With this tech that is an Eaton Patent, you dont need to build an exhausts for evacuate the gases put of the room or the building.

The portal is a great learning curve for a unemployed technician like me.I learn alot the explanation is cleared, keep up the excellent updates.

Hi sir this is Vasu deva Using current that much 6300amps if you can decrease it to required value of industries and etc., requirements they can get as much current or Power they require by using the current transformers,we mainly use the voltage, increasing of current not only leads to power loss(i^2r), it will effect morely on human beings morely on animals.

So by decreasing the current rating we can get good output.

Thank you sir

I have been following every article you post and for sure they are of great help to my life.

Good knowledge you share here.

Hi I’m qc manager in the mv switch gear company we need to contact to your company to made your switchgear

Great effort and service to Electrical engineering. We are a foremost electrical installation works company in Africa handling various major industrial and power engineering projects In Nigeria and many African countries. We would love know you more to find areas of business collaboration. Thanks