Generation

In present day world, wind power has become one of the rapidly growing energy resources and have even become challenging to the other conventional resources and now have become more quieter and efficient too.

A revolutionary change in the wind power generation sector is the introduction of offshore floating wind turbines and the idea was given for the first time by Prof. William. E. Heronemus at the University of Massachusetts Amherst in 1972.

But it was decommissioned by the end of 2008 after collecting the necessary test data on wind and sea conditions. Thereafter, came the word’s first operational offshore wind turbine, Hywind, of 2.3MW capacity in 2009 in Norway with its installation credit bagged by Statoil.

It was then followed by many such successful implementations by leading ventures like Wind Plus.

As we all know, offshore winds are much more powerful as well as consistent and hence it renders a great opportunity for engineers to make use of it to meet the tremendously rising energy needs to a great extent with less aesthetic impact.

Because,

Wind Power, P =1/2 ρ A V3

Where:

ρ = air density,

A = swept area of turbines, V = wind speed

From this, one could infer that the wind power is proportional to the cube of the wind velocity. Since, offshore wind velocity is greater than that of onshore, it became evident that more power could be obtained thereof.

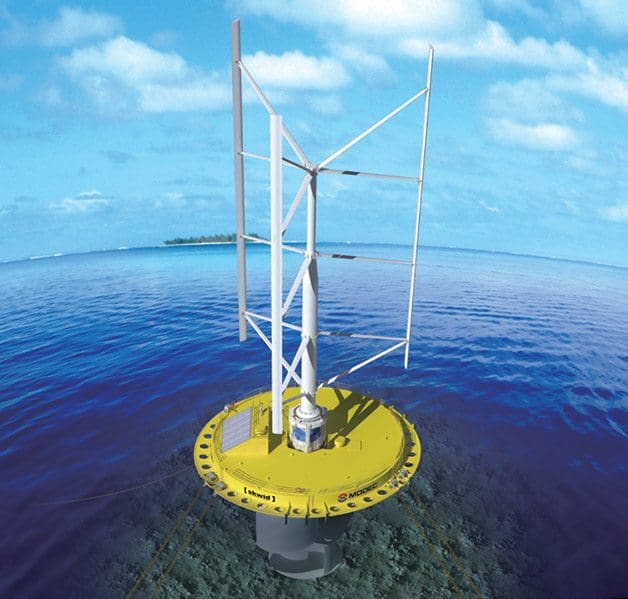

At first, limitations in technologies made it’s installation limited to less deep waters, but nowadays, deep and ultra deep water deployments have become a reality to access more denser resource. The wind turbine is mounted on a floating platform and is moored to the ocean floor.

An offshore wind turbine consists of:

- Rotor blades,

- Nacelle,

- Tower,

- Floating hull and

- Mooring lines.

Also, there is an anemometer at the top of the turbine to record the speed and direction of the wind. Commonly, there are three principal ways of anchoring this floating structure viz: tension leg mooring system, catenary mooring system and ballasted catenary mooring system.

This type of mooring considered to be cost effective too. But the most common type of mooring in shallow waters is catenary mooring and the suspended weight of these mooring lines provides the restoring force, hence efficiently fastening the floating structure.

In order to achieve more stability, ballast weights are employed to add additional cable tension and thereby stiffness to the floating structure.

Hywind, worlds first offshore floating windmill

Since to contribute a considerable amount of power, a number of wind turbines have to be employed which collectively results in an offshore floating wind farm. And the power developed in these wind farms are transmitted to onshore grids via underground cables.

Actually, the rotating blades are connected to a rotor which is inturn attached to a shaft linking the rotating part of a generator, all enclosed in the nacelle.

The energy thus generated is taken down the wind tower via cables and from there to the transformer platform associated with each wind farm for stepping up. Finally, the power is transmitted to the onshore electrical grids via submarine cables and from there to domestic users.

But a problem faced in this context is the unpredictable nature of the wind resource.

And as a redressal to it, SeaTwirl deployed their first floating grid in 2011 with wind turbines which possessed an additional feature, a fly wheel intended to store energy to maintain continuous energy supply though the wind has stopped blowing. It was yet another milestone in the advancement of these offshore wind turbines.

One great advantage of these offshore structures is that they could tame the deadly hurricanes encountering them by reducing the peak wind speed.

Also, studies have proven that vertical axis wind turbines are further cost effective when compared to horizontal axis turbines, thus providing a solution to the drawback of high installation cost. Because, its careful designing could result in ten times more power output as compared to horizontal axis turbine of same size.

Moreover, vertical axis wind turbines consumes only less space, thus we could accommodate more turbines in the space provided and they are quieter too.

In the perspective of economic installation, almost all the assemblings are done onshore also and finally deployed by means of specialised vessels.

Advantages:

- Green Electricity

- Less aesthetic impact

- New habitat to seabed dwelling creatures

- Resists hurricanes like natural calamities

- More strong resource

- Computer & scale models avoids costly failures

Disadvantages:

- Effects on fish movement, though minor

- High installation and maintenance cost

- Certain marine safety risks

The electricity generated in this way is absolutely green electricity since it lacks burning of any fuels resulting in the emission of green house gases. Thus, researches are going ahead to find effective remedies to these draw backs and to ensure the supply of this green electricity to millions of households in future.

Adventures Knowledge for us & shall help in the future in INDIA also.

Best Regards,

Amey

Excellent work sajna.. it helped us for our project..

you mentioned so many advantages for vertical axis wind turbines, but I guess there are more horizontal axis turbines in commercial generation. Any reasons or am I wrong?

Great article btw.

Thank you, and I have work in wind sector for on Shore…

and I am interested in off-shore wind Project.

Superb work ……..

Innovative neethu

Innovative and good work sajna

Excellent article Sajna! Thank you very much!

Thank you sir…

Inspiring! Hopeful! Good article.

It seems that the converters were from my company, so they must be very robust!

sir,

EEP is excellant PORTAL