They are simple in construction. The major parts of a minimum oil circuit breaker excluding the poles are the base frame,the drive which is constructed as a stored energy opening and closing mechanism (the operating mechanism). The opening spring of the stored energy mechanism is charged automatically during the closing action. The closing spring is charged either by means of an electric motor (is built into the drive housing) or by means of a removable crank.

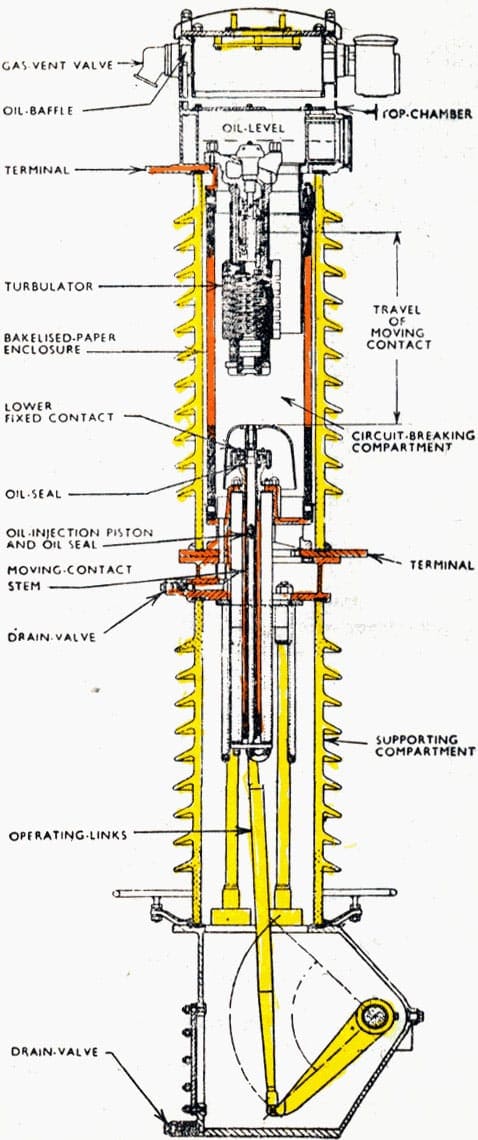

The pole constitute of: insulating cylinder, arc chamber, fixed, guiding and moving contacts. It also has the gas expansion chamber, terminals, oil sump, oil draining and oil filling plugs and the oil level indicator.

Arc Interruption in Oil

On separation of the moving contact from the fixed contact in the arc chamber, the current continues to flow through the vaporizing metallic current paths. The high temperature occurring under such conditions, decomposes the oil (which boils at 658°K), in the immediate vicinity and a gas bubble is formed (under high pressure).

It consists of (from outside inward): wet oil vapour, superheated oil vapour, hydrocarbons (C2H2 at around 4000°K), the arc (approximate temperature 7000°K) as shown in Figure 1.

Explanation

- CF4 – Carbon Tetrafluoride

- CuF2 – Copper Difluoride

- HF – Hydrogen Fluoride

- H2O – Water

- SF4 – Sulphur Tetrafluoride

- SF6 – Sulphur Hexafluoride

- SO2 – Sulphur Dioxide

- SO2F2– Sulphuryl Fluoride

- SOF2 – Thionyl Fluoride

- WF6 – Tungsten Hexafluoride

- WO3 – Tungsten Trioxide

Also, the gas in the arc chamber escapes to the gas expansion chamber, so that a type of heat dissipation by convection is created, thus the rate at which heat is dissipating is increasing. Near current zero, the thermal power generated by the current (in the arc) approaches zero.

If the heat dissipation outwards is sufficiently large, the temperature in the arc zone can be reduced in such a manner that the arc would lose conductivity and extinguish. An arc in hydrogen has a short thermal time constant, so that the conditions are favourable for quenching. There are two other situations that may occur under certain conditions: thermal Restriking of Arc, reignition.

Thermal restriking is when the post-arc current rises again and passes into the next half cycle of SCC, as the arc plasma heats up due to the insufficiency of heat dissipation to make conductance of the arc zone equal to zero. Reignition happens when therestriking voltage of the system causes a renewed formation of the arc, (after completion of the first interruption) and continuation of flow of current. The arcing chamber designs are either of the axial or radial venting type. Often, a combination of both are used in the design of minimum oil, MV CB’s.

The axial venting process generates high gas pressures and has high dielectric strength. This is used mainly for interruption of low currents. The radial venting is used for high current interruptions, as the gas pressures developed are low and the dielectric strength is low.

The higher the current to be interrupted, the larger the gas pressure developed.

Resource: Vepi – The Electrical Power Systems Division; The Switchgear & circuit breakers section

GES Switchgear Pvt Ltd is one of the foremost Switchgear and Air Circuit Breaker Manufacturer in India offering most trusted products.

For more info, Click

http://goo.gl/XhXybx

Nice concise article!