Four important tests and checks

The pre-commissioning tests need to be carefully programmed so that they take place in a logical and efficient order, in order that no equipment is disturbed again during subsequent tests. Before starting the tests, it is essential to ensure that the assembly of the particular item being tested has been completed and checked.

The most important pre-commissioning tests and in-service checks of protection system can be summarized as follows:

- Analysis of the wiring diagrams to confirm the polarity of connections, positive and negative-sequence rotation, etc.

- A general inspection of the equipment, physically verifying all the connections, at both the relay and panel terminations

- Measurement of the insulation resistance of the protection equipment

- Inspection and secondary injection testing of the relays

- Testing current transformers

- Checking the operation of the protection tripping and alarm circuits

In addition, the list of the tests to be carried out should be arranged in a chronological order together with any precautions that need to be taken into account. Some of the more usual tests are briefly described below.

Pre-commissioning tests

- Insulation resistance measurement

- Secondary injection tests

- Current transformer tests

- Primary injection test

1. Insulation resistance measurement

This test should be carried out with the aid of a 1000V insulation resistance meter. It is difficult to be precise as to the value of resistance that should be obtained. The climate can affect the results – a humid day tends to give lower values, whereas on a dry day much higher values may be obtained.

2. Secondary injection tests

These tests are intended to reproduce the operating conditions for each relay and are limited solely to the protection as such, so that it is important to read and understand the relay instruction manual (application, operation, technical characteristics, installation and maintenance).

Although the relays should have been carefully tested in the manufacturer’s works, it is necessary to make some checks on site after they have been mounted on the panels in order to be sure that they have not been damaged in transit to the installation. The actual tests carried out on the relays depend largely on the type of relay.

Secondary injection tests are required to ensure that the protective relay equipment is operating in accordance with its preset settings.

Relay inputs and outputs must be disconnected prior to perform these tests. The test equipment supplies the relay with current and voltage inputs that correspond to different faults and different operating situations. Pick-up values are reached by gradually changing the magnitudes of these inputs while simultaneously measuring the relay operating time.

Tripping contacts and targets must be monitored during these tests in order to ensure that the relay is working according to the manufacturer’s specifications and the settings that have been implemented.

If the curves and characteristics of a relay are to be tested at many points or angles, it is convenient to use test equipment that can conduct a test automatically. Modern protective relay test equipment has the option of performing automatic tests aided by software programs, for which the testing process is much faster and more precise.

In addition, the time during which the relay is out of operation is minimized.

Figure 1 shows a typical layout of a protective relay test equipment. This equipment is able to provide current and voltage injection as well as phase shift when testing directional protection. It thus permits testing of a wide variety of relay types such as overcurrent, directional overcurrent, reverse power, distance and under/overvoltage units.

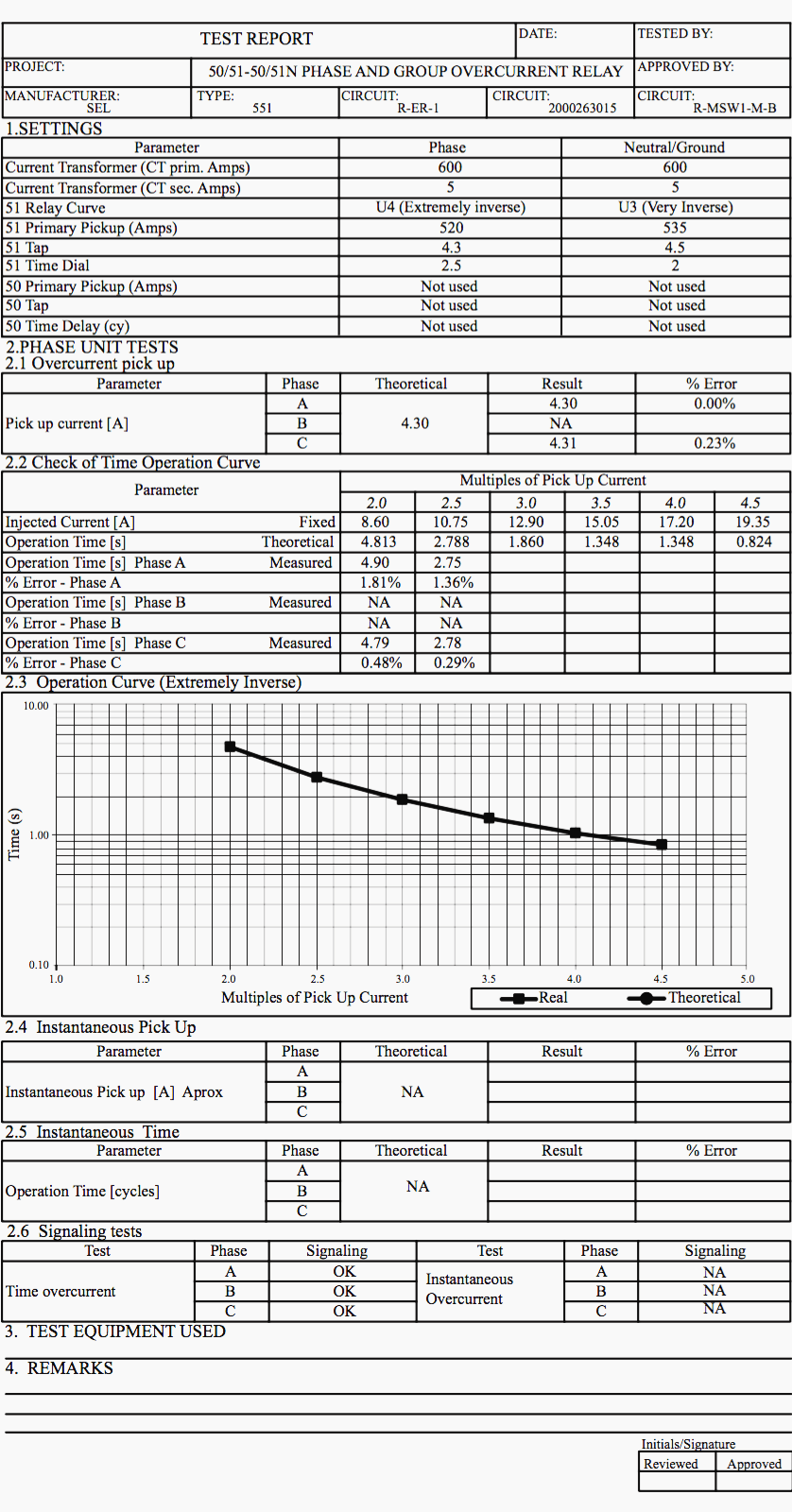

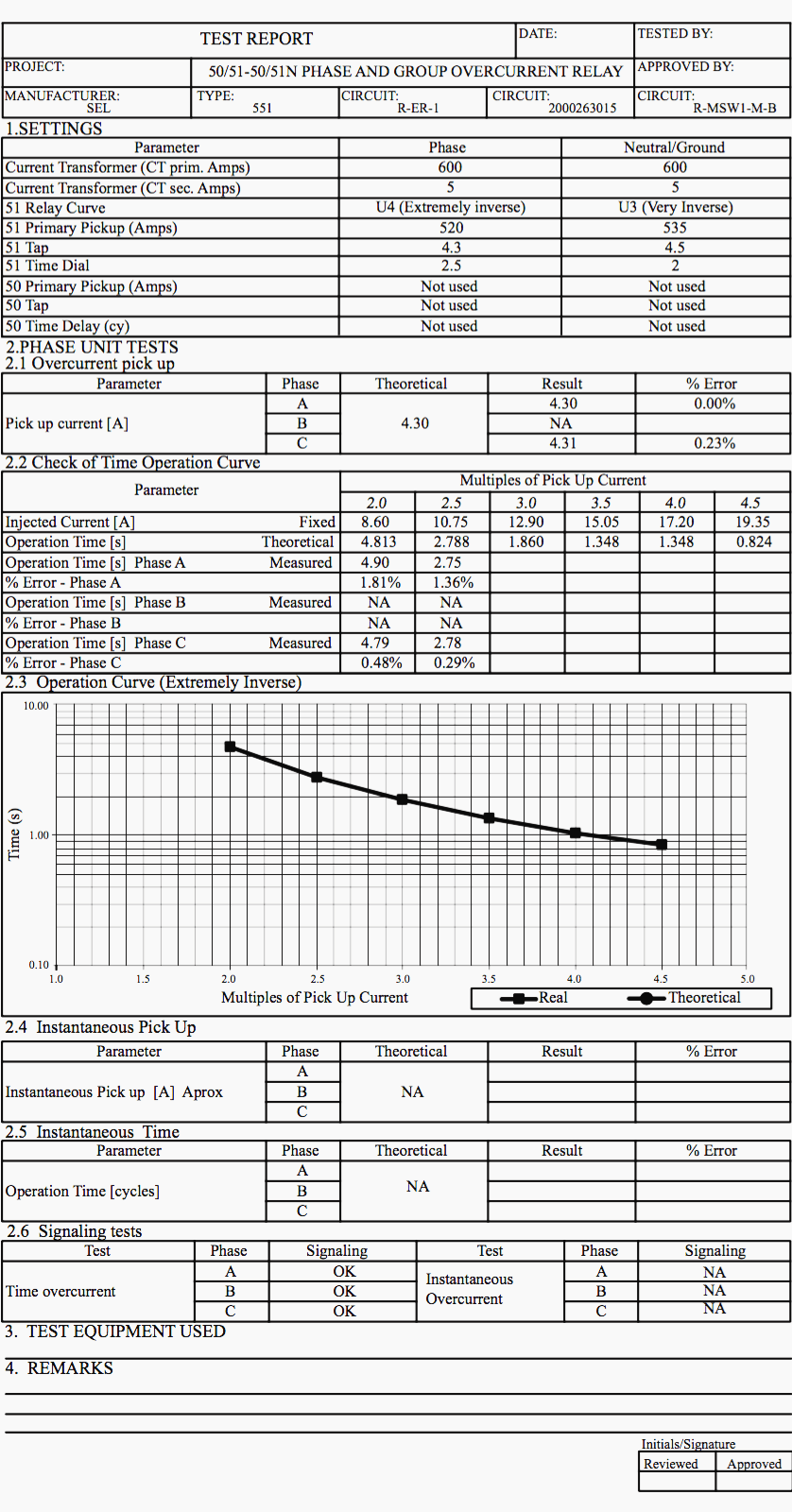

For example, a typical pro forma for overcurrent relay tests, as shown in Figure 2 below, could have the following information recorded:

- Basic data about the circuit supplying the relay.

- The settings used before any tests commenced, which had been applied in accordance with the protection coordination study. This information should include the pick-up current, time dial and instantaneous settings.

- Operating times for different multipliers, as measured by calibration tests. These should be checked against the data provided by the manufacturer.

- Test data for the instantaneous units.

- Finally, the equipment used in the test should be recorded together with any relevant observations, plus details of the personnel who participated in the test.

It is important to note that the tests referred to beforehand correspond to steady-state conditions, and the equipment to carry them out is rather conventional. As a consequence of technological developments, more sophisticated equipment is now available to undertake tests using signals very similar to those that exist during fault conditions.

Since relays are required to respond to the transient conditions of disturbed power systems, their real response can be assessed by simulating the signals that go to the relays under such conditions. Several manufacturers offer equipment to carry out dynamic-state and transient simulation tests.

A dynamic- state test is one in which phasor test quantities representing multiple power system conditions are synchronously switched between states. Power system characteristics, such as high frequency and DC decrement, are not, however, represented in this test.

A transient simulation test signal can represent in frequency content, magnitude and duration, the actual input signals received by a relay during power system disturbances.

3. Current transformer tests

Before commissioning a protection scheme, it is recommended that the following features of current transformers are tested:

Overlap of CTs

When CTs are connected in order that a fault on a breaker is covered by both protection zones, the overlap connections should be carefully checked. This should be carried out by a visual inspection.

If this is not possible, or difficult, a continuity test between the appropriate relay and the secondary terminals of the appropriate CT should be carried out.

Correct connection of CTs

There are often several combinations of CTs in the same bushing and it is important to be sure that the CTs are correctly connected to their respective protection. Sometimes all the CTs have the same ratio but much different characteristics, or the ratios are different but the CTs are located close together, which can cause confusion.

Polarity

Each CT should be tested individually in order to verify that the polarity marked on the primary and secondary windings are correct. The measuring instrument connected to the secondary of the CT should be a high impedance voltmeter or a moving coil ammeter, with centre zero. A low voltage battery is used in series with a push-button switch in order to energise the primary.

When the breaker is closed the measuring instrument should make a small positive deflection, and on opening the breaker there should be a negative deflection, if the polarity is correct.

4. Primary injection test

This test checks out all the protection system, including the current transformers. The principal aims of this test are to verify the CT transformation ratios and all the secondary circuit wiring of both the protection and the measurement CTs so that the operations of the tripping, signalling and alarm circuits are confirmed.

Figure 3 shows the schematic diagram of a typical equipment used for carrying out primary injection tests.

The test current is usually between 100 and 400 A. The two high current terminals of the primary injection equipment marked and should be temporarily connected to the terminals of the CT that is being tested.

Reference // Protection of Electricity Distribution Networks by Juan M. Gers and Edward J. Holmes at The Institution of Engineering and Technology (Purchase hardcopy from Amazon)

What great display of electrical boards and switching sequence boards, and to see them getting tested and seeing the instruments being used, and the test sheets. It shows the young electrical engineers of what you can attain. I won’t go into the technical side of the boards and the switching only to say it’s impressive and in years gone by I may have been able understand it all but can still understand the drawing but to all the young engineers out there is look and learn.

Regards

JP.

Buenas tardes cuando se apertura el curso, gracias

Bon soir M Edvard.

Je trouve votre activité un vrai trésor d’informations sur la phase mise en service des équipements Mt.merci de nous trouver des vidéos en français qui explique le teste des relais de protection avec la valise d’injection.

Un grand merci .