Calculate size of each part of DOL motor starter for the system voltage 415V, 5HP three phase house hold application induction motor, code A, motor efficiency 80%, motor RPM 750, power factor 0.8 and overload relay of starter is put before motor.

Basic Calculation of Motor Torque and Current

- Motor Rated Torque (Full Load Torque) = 5252xHPxRPM

- Motor Rated Torque (Full Load Torque) = 5252x5x750 = 35 lb-ft.

- Motor Rated Torque (Full Load Torque) = 9500xKWxRPM

- Motor Rated Torque (Full Load Torque) = 9500x(5×0.746)x750 = 47 Nm

- If Motor Capacity is less than 30 KW than Motor Starting Torque is 3xMotor Full Load Current or 2X Motor Full Load Current.

- Motor Starting Torque = 3xMotor Full Load Current.

- Motor Starting Torque = 3×47 = 142Nm.

- Motor Lock Rotor Current = 1000xHPx figure from below Chart/1.732×415

Locked Rotor Current

| Code | Min. | Max. |

| A | 1 | 3.14 |

| B | 3.15 | 3.54 |

| C | 3.55 | 3.99 |

| D | 4 | 4.49 |

| E | 4.5 | 4.99 |

| F | 5 | 2.59 |

| G | 2.6 | 6.29 |

| H | 6.3 | 7.09 |

| I | 7.1 | 7.99 |

| K | 8 | 8.99 |

| L | 9 | 9.99 |

| M | 10 | 11.19 |

| N | 11.2 | 12.49 |

| P | 12.5 | 13.99 |

| R | 14 | 15.99 |

| S | 16 | 17.99 |

| T | 18 | 19.99 |

| U | 20 | 22.39 |

| V | 22.4 |

- As per above chart Minimum Locked Rotor Current = 1000x5x1/1.732×415 = 7 Amp

- Maximum Locked Rotor Current = 1000x5x3.14/1.732×415 = 22 Amp.

- Motor Full Load Current (Line) = KWx1000/1.732×415

- Motor Full Load Current (Line) = (5×0.746)x1000/1.732×415 = 6 Amp.

- Motor Full Load Current (Phase) = Motor Full Load Current (Line)/1.732

- Motor Full Load Current (Phase) = 6/1.732 =4Amp

- Motor Starting Current = 6 to 7xFull Load Current.

- Motor Starting Current (Line) = 7×6 = 45 Amp

1. Size of Fuse

Fuse as per NEC 430-52

| Type of Motor | Time Delay Fuse | Non-Time Delay Fuse |

| Single Phase | 300% | 175% |

| 3 Phase | 300% | 175% |

| Synchronous | 300% | 175% |

| Wound Rotor | 150% | 150% |

| Direct Current | 150% | 150% |

- Maximum Size of Time Delay Fuse = 300% x Full Load Line Current.

- Maximum Size of Time Delay Fuse = 300%x6 = 19 Amp.

- Maximum Size of Non Time Delay Fuse = 1.75% x Full Load Line Current.

- Maximum Size of Non Time Delay Fuse = 1.75%6 = 11 Amp.

2. Size of Circuit Breaker

Circuit Breaker as per NEC 430-52

| Type of Motor | Instantaneous Trip | Inverse Time |

| Single Phase | 800% | 250% |

| 3 Phase | 800% | 250% |

| Synchronous | 800% | 250% |

| Wound Rotor | 800% | 150% |

| Direct Current | 200% | 150% |

- Maximum Size of Instantaneous Trip Circuit Breaker = 800% x Full Load Line Current.

- Maximum Size of Instantaneous Trip Circuit Breaker = 800%x6 = 52 Amp.

- Maximum Size of Inverse Trip Circuit Breaker = 250% x Full Load Line Current.

- Maximum Size of Inverse Trip Circuit Breaker = 250%x6 = 16 Amp.

3. Thermal Overload Relay

Thermal Overload Relay (Phase):

- Min. Thermal Overload Relay setting = 70%x Full Load Current(Phase)

- Min. Thermal Overload Relay setting = 70%x4 = 3 Amp

- Max. Thermal Overload Relay setting = 120%x Full Load Current(Phase)

- Max. Thermal Overload Relay setting = 120%x4 = 4 Amp

Thermal Overload Relay (Phase):

- Thermal Overload Relay setting = 100% x Full Load Current (Line).

- Thermal Overload Relay setting = 100%x6 = 6 Amp

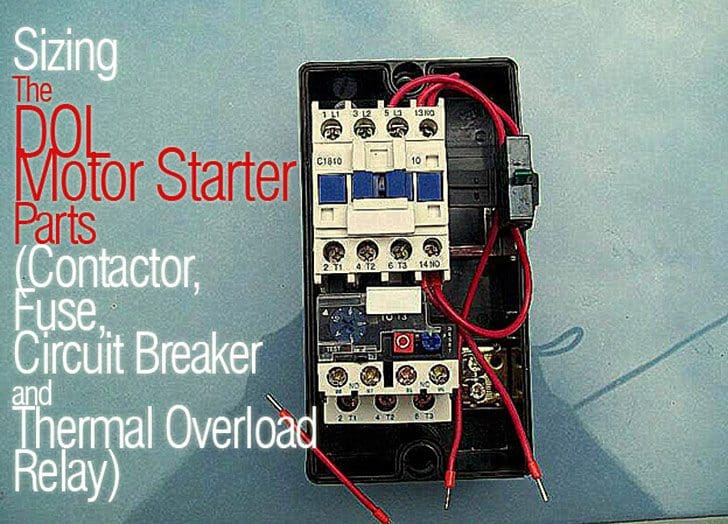

4. Size and Type of Contactor

| Application | Contactor | Making Cap |

| Non-Inductive or Slightly Inductive ,Resistive Load | AC1 | 1.5 |

| Slip Ring Motor | AC2 | 4 |

| Squirrel Cage Motor | AC3 | 10 |

| Rapid Start / Stop | AC4 | 12 |

| Switching of Electrical Discharge Lamp | AC5a | 3 |

| Switching of Electrical Incandescent Lamp | AC5b | 1.5 |

| Switching of Transformer | AC6a | 12 |

| Switching of Capacitor Bank | AC6b | 12 |

| Slightly Inductive Load in Household or same type load | AC7a | 1.5 |

| Motor Load in Household Application | AC7b | 8 |

| Hermetic refrigerant Compressor Motor with Manual O/L Reset | AC8a | 6 |

| Hermetic refrigerant Compressor Motor with Auto O/L Reset | AC8b | 6 |

| Control of Restive & Solid State Load with opto coupler Isolation | AC12 | 6 |

| Control of Restive Load and Solid State with T/C Isolation | AC13 | 10 |

| Control of Small Electro Magnetic Load ( <72VA) | AC14 | 6 |

| Control of Small Electro Magnetic Load ( >72VA) | AC15 | 10 |

As per above chart:

- Type of Contactor = AC7b

- Size of Main Contactor = 100%X Full Load Current (Line).

- Size of Main Contactor = 100%x6 = 6 Amp.

- Making/Breaking Capacity of Contactor = Value above Chart x Full Load Current (Line).

- Making/Breaking Capacity of Contactor = 8×6 = 52 Amp.

What are the suitable contactor, breaker, and overload for 30hp, 22kw and 42A

refer to IEC standard, what is maximum motor rating on DOL ?

I want to know the right contactors for?

15hp-motor——contactor size

20hp–!!————–!!

30hp–!!————–!!

7.5hp–!!————-!!

Characteristics of Contactors and Starters (IEC 60947-4)

(Modification-1) Shall be AC-4 rated.

(Addition-1) Rated Insulation Voltage shall be a minimum of 660 VAC.

(Modification-2) Shall be rated for uninterrupted duty.

(Addition-2) Rated Operational Current shall be a minimum of 24 A.

(Addition-3) Contactors for motor service shall be selected based upon the

following:

a) On the assumption that all motors operate under 90% AC-3 duty and

10% AC-4 duty

Question:

As per the requirement of the specification ..the contactor Ampere rating for shall be minimum 24A for even for the motor will Less KW loads .

if Coordination is between MPCB,overload and motors there any impact of Contactor if it is oversized?

Current setting of thermal overload relay.

थर्मलर्म ओवर लोड रिले की करंट सैटिंसै गटिं की जाती है।

Option 1 : According to noted current on motor name plate / मोटर नेम प्लेट पर अंकिअं त धारा के अनुसा नु र

Option 2 : On 15% less of supply voltage / सप्लाई वोल्टेज के 15% कम पर

Option 3 : On 10% more of supply voltage / सप्लाई वोल्टेज के 10% अधिक पर

Option 4 : On 10% less load current / भार धारा के 10% कम पर

There is a typographical error in the equation for Max Rated Torque. It should have been 9500 x KW / RPM; 5252 x HP / RPM

Thanks Vinay to inform about the error regarding to writedown the equation

Hi, we have a 425hp FCMA starter for motor. We have used Run contactor 1050A where as customer had prescribed for 800A. And start contactor 800 we have used whereas customer needed 500A. Does this create any problem with the product performance. Please suggest.

why hp not watt is being used for drawing Motor lock rotor current?

Dear

first thank you for this website with my wish for more successful, if i have a 92 kw/380v/0.8/184 amp submersible pump and i want to reduce the inrush current how much could reduce the starting current if i use soft starter,

your truly

for induction motor I will use AC7b?

How will you calculate the contactor, Motor Protection circuit breaker, Molded CasecCircuit Breaker, thermal overload and size of power cable and control cable for DOL starter and Star Delta Starter Upto 5 HP & Above 5 HP induction motor. Thank u.

I don’t know how 8×6 becomes 42 in your calculation.

In fact the release shows that 8×6= 52 and not 42, but it also is wrong as well, so some correction or complementary variable and numbers must be added in this equation in order to explain this result.

Which contactor is best suitable for 110kw/150hp slip ring induction motor…stator current196amp/rotor current275amp

8×6=52 How it is possible

Can you please explain . How Motor rated torque value is 35 lb-ft????

How it’s 5252*5*750=35 lb-ft it’s coming 19,695,000 please clarify..

motor rated or full load torque= 5252XHp / RPM

5252*5/750=35 T=5252*HP/RPM

A motor full load current ratting 20 amp .how olr setting formula

20×1.5=30

May you please explain how it is possible to have the Motor Starting Current (Line) = 45 Amp bigger than the

Maximum Locked Rotor Current = 22 Amp?

hi

plz send me 0.5 hp, 1 hp and 10 hp motor slide rules

i think there is something wrong on the value of F max., it should be 5.59 not 2.59 under locked rotor current.

Hi,

I have an EC-DC motor of 0.4 KW. I want to command the motor from a PLC output 24 AC and i want to control the speed of the motor with 0-10 vdc. Could you please guide me for selection of control relay for starting the motor. The motor data is 230 VAC 50Hz single phase.

Also can i use control relay for commanding the motor On and Off.

The page before was better because it allowed copying or downloading what I published in PDF now and only lets print it bad that bad serivicio. I was better before.

Where can I find the required magnetic contactor size for a motor given the motor current or HP?

Hi,

I need tips on how to do sizing of UPS & Automatic Power Factor Correction

We are going to manu.. 2HP single phase monoset pump for agriculture purpose.240V & max curretnt 11.5A. difficulty is i am not getting that how much degree of thermal fuse we can use?

Mr.shafqat

I have a question for you.

I have a two speed motor having twelve(12) input terminals.when we provide supply on twelve terminals what happend???????

Pls I want to know why you chose motor starting torque to be 3x full load current. Thanks

Dear Gents

Please support me to select fuse size for 3 phase motor with LRA 11.4 A V=400, inpout power 1.21Kw, current = 2.3A and how to calculat it?, fause PH (3N)

how we select aa magnetic contactor wth respect to motor

Dear Sir/Mam ,

I have completed bachelor’s degree in Electrical & Electronics engineering branch in 2014 . I have 6months experience in designing electrical panels ( APFC, MCC & PCC panels)& switchgears and software skills in electrical autocad.

Can you please suggest doing PLC, SCADA automation course will hike up my career or not

to get a higher package. If yes please do suggest Institutes for the same

Regards

Sanjul

The starting current is 45A , maximum size of none time delay fuse is 11A ,

Why it will not blow?

Why Code F minimum locked rotor current =5A , maximum locked rotor current =2.59A

Motor starting torque=3 times of motor full load torque or current

3 times or 2 times it is very big difference

i want to know how many torque of 15 kw motor

How will you calculate the contactor, circuit breaker, thermal overload and size of power cable and control cable for DOL starter when u are give a 3KW induction motor. Thank u.

what are the basis for above calculations?

What is the basis of above calculation….

Provide International Standard for Calculation….

Thank you

1.Can we say what is the no load current for a motor if it’s full load current,voltage,power ,power factor are known

5252x5x750 = 35 lb-ft. ????

9500x(5×0.746)x750 = 47 Nm ???????

It should be:

5252×5/750 = 35 lb-ft.

9500x(5×0.746)/750 = 47 Nm

Yes u r right

From where you got multiplying factor, Is there any std/ ref in IS, IEC.etc.

Motor Full Load Current (Line) = KWx1000/1.732×415

Why the power factor is not included in the calculation although it has been give in the details?

p.f is taken in the calculation, but it is missing in the formula

great sir,can u describe about selection of transformer according to connected load, necessary erection steps for transformer erection