Internal arcing in an oil-filled power transformer can instantly vaporize surrounding oil, generating gas pressures that can cause catastrophic failure, rupture the tank, and spread flaming oil over a large area.

This can damage or destroy other equipment in addition to the transformer and presents extreme hazards to workers.

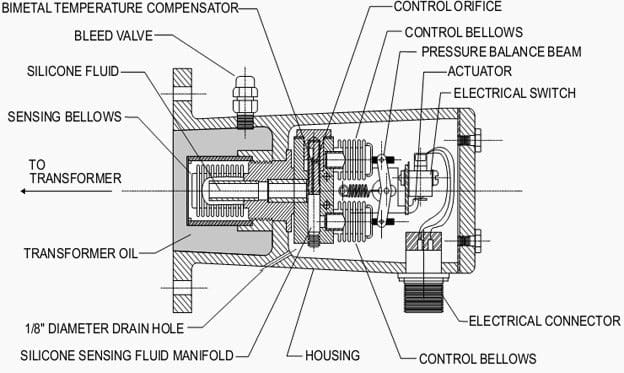

Modern sudden pressure relays consist of three bellows (see figure 1) with silicone sealed inside. Changes in pressure in the transformer deflect the main sensing bellows. Silicone inside acts on two control bellows arranged like a balance beam, one on each side. One bellows senses pressure changes through a small orifice. The opening is automatically changed by a bimetallic strip to adjust for normal temperature changes of the oil.

The orifice delays pressure changes in this bellows. The other bellows responds to immediate pressure changes and is affected much more quickly. Pressure difference tilts the balance beam and activates the switch.

This type relay automatically resets when the two bellows again reach pressure equilibrium. If this relay operates, do not re-energize the transformer until you have determined the exact cause and corrected the problem.

Old style sudden pressure relays have only one bellows. A sudden excessive pressure within the transformer tank exerts pressure directly on the bellows, which moves a spring-loaded operating pin. The pin operates a switch which provides alarm and breaker trip. After the relay has operated, the cap must be removed and the switch reset to normal by depressing the reset button.

Maintenance of sudden pressure relay

Once every 3 to 5 years, the sudden pressure relay should be tested according to manufacturer’s instructions. Generally, only a squeeze-bulb and pressure gage (5 psi) are required. Disconnect the tripping circuit and use an ohmmeter to test for relay operation.

Test the alarm circuit and verify that the correct alarm point is activated. Use an ohmmeter to verify the trip signal is activated or, if possible, apply only control voltage to the breaker and make sure the tripping function operates.

Consult the manufacturer’s manual for your specific transformer for detailed instructions.