Content

- Environmental Concerns

- Safety Concerns

- Special Handling Procedures

- Installation Concerns

- Operation and Maintenance Concerns

- End of Life / Recycling Concerns

- Conclusion

Introduction to GIS (Gas Insulated Switchgear)

Medium voltage (5-38 kV) gas insulated switchgear (GIS) differs greatly from the medium voltage AIS – Air insulated switchgear commonly used in North America Instead of using air and solid insulation materials, GIS switchgear has the vacuum interrupter and bare bus conductors in a sealed housing filled with an insulating gas.

1. Environmental Concerns

The insulating gas used in MV GIS switchgear, sulfur hexafluoride (SF6), is a highly potent greenhouse gas with a global warming potential 23,900 times greater than CO2. SF6 also has an atmospheric life of 3,200 years, so it will contribute to global warming for a very long time.

(Source: EPA website www.epa.gov/electricpower-sf6)

2. Safety Concerns

In its normal state, SF6 gas is:

- Colorless,

- Odorless,

- Non-flammable, and

- Non-toxic to humans.

However, under high temperature conditions (> 350 degrees F), SF6 decomposes into products that are toxic and corrosive. Decomposition by-products can occur when SF6 is exposed to spark discharges, partial discharges, switching arcs and failure arcing.

These byproducts, in the form of gases or powders, can cause the following conditions in humans:

- irritation to the eyes, nose, and throat,

- pulmonary edema and

- other lung damage, skin and eye burns, nasal congestion, bronchitis;

- powders may cause rashes.

(Source: EPA website www.epa.gov/electricpower-sf6)

However, it should be noted that the test results may differ if the tests were done with SF6.

When a dielectric failure occurs in a GIS, the arc generally will not be extinguished by the SF6, and could lead to internal pressure build up and cause holes in metal walls due to concentrated buming of the arc. GIS manufacturers just state that the GIS equipment is “inherently” arc resistant, but in reality an arc can very well live within the GIS.

Also it is well known that all SF6 containments leak, therefore, the chances of having an issue with GIS is more prevalent than ever having an arc issue within non arc resistant switchgear.

Utilizing other solutions, such as designs that use complete single pole solid insulation, partial discharge sensors for insulation diagnostics, and remote racking for safety, the non arc resistant solution easily exceeds the safety of GIS.

3. Special Handling Procedures

Due to the safety concems, special handling procedures are recommended for heavily arced SF6 including the use of personal protective equipment (PPE – i.e., respiratory device, protective clothing such as rubber gloves, footwear, goggles) for removal/handling of solid SF6 byproducts.

Contaminated SF6 gas must either be filtered on-site using special mobile equipment or removed for off-site filtering or destruction using trained personnel.

(Source: EPA website www.epagovlelectricpower-sf6)

4. Installation Concerns

The most significant installation issues involve the need for proper alignment. The foundation must be level and in a single plane to allow for proper assembly of the shipping sections. The foundation height can only vary by 1 mm per meter, with a maximum deviation of 2 mm over the full length of the assembly.

After installation of the GIS shipping groups, equipment must be sealed and SF6 is filled at site.

Another issue is power cable connections are not accessible without disassembling the switchgear.

(Source: IEEE Transaction on Industry Applications, Vol. 40. No. 5, September! October 2004 and Eaton experience.)

5. Operation and Maintenance Concerns

Because SF6 gas provides insulation of internal components, draw out circuit breaker designs are not possible. Most local codes require that the design of equipment incorporate a means to visually verify the isolating function of disconnect devices.

In the GIS switchgear, this requires a means to visually verify the position of the three-position switch. To meet this requirement, some manufacturers install miniature video cameras, and associated lighting, both mounted external to the SF6 gas enclosure.

The video leads are brought to the front panel of the switchgear, and a monitoring device is provided to view the position of the switch.

Cant see this video? Click here to watch it on Youtube.

(Source: IEEE Transaction on Industry Applications, Vol. 40, No. 5, September I October 2004)

6. End of Life and Recycling Concerns

Used SF6 gas must be recovered by trained professionals, then stored and transported in US Department of Transportation (DOT) approved cylinders for the final recycle process. DOT regulations require equipment containing SF6 gas at pressures greater than 25 psig at 68° F to be certified to transport compressed gas.

(Source: EPRI Guidelines for Safe Handling of SF6, DOT CFR 49 Chapter l Subchapter C)

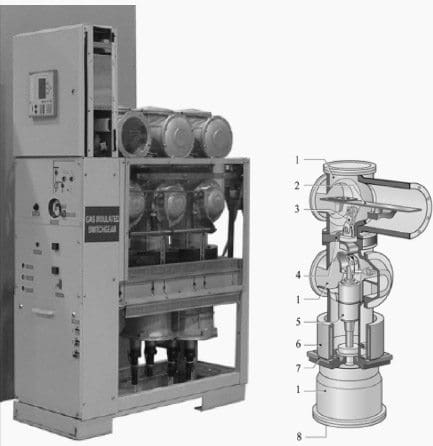

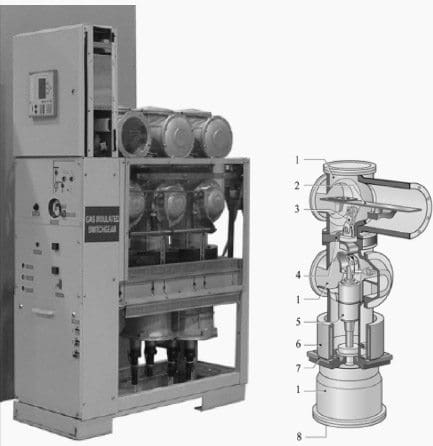

GIS differs greatly from traditional MV Metal Clad switchgear widely used in North America. A view of one pole of a typical unit of GIS switchgear is shown in Figure 1.

1 – Cast aluminium housing

2 – Main bus bars with sliding supports

3 – Three-position selector switch

4 – Gas tight bushing

5 – Vacuum interrupter

6 – Toroidal current transformer

7 – Capacitive voltage transformer

8 – Shock-proof (safe-to-touch) cable termination (not shown)

As in air insulated Metal Clad switchgear, vacuum circuit breakers are used for interruption.

Conventional MC switchgear relies on a combination of air and solid insulating materials, but GIS switchgear uses bare bus conductors on insulating supports, immersed in insulating gas.

Conclusion

Due to the environmental concerns, installing medium-voltage GIS switchgear is not consistent with the Sustainability Principles and Greenhouse Gas reduction goals of many leading edge corporations and institutions.

The safety and special handling concems could raise issues with internal Environmental Health and Safety policies.

Finally, the installation, operation and maintenance and end of life/recycling concerns associated with medium voltage GIS switchgear can raise the total cost of ownership and may not be the best value solution.

Alternative solutions include AIS – air insulated switchgear and solid insulated switchgear designs that avoid the use of SF6 gas and can offer a lower total cost of ownership over the complete life cycle of your medium voltage equipment.

Resource: EATON CORPORATION

Typical example of non-SF6 promoters. Worried about its own bussiness, not enviroment.

Difficult to belive that all in SF6 gear is a great disadvantage.

What about metal byproducts after internal arc? Quite more dangerous than SF6 byproducts, but never present in the explanations.

Please, read and compare by yourself

Really an eye opener, but we do not have a choice!

Mr. Edvard, I would like to inquire the full description of SF6 fused type ring main unit CTC-F or RM6 type. thanks. Edd