Transformer constructions

Liquid filled, ventilated dry and gas filled dry types

There are several different types of transformer constructions you can see installed in substations inside commercial and other buildings. This article is generally applicable only to transformers of the liquid filled, ventilated dry, or gas filled dry types.

Liquid insulated and gas filled transformers have their windings brought out to bushings or to junction boxes on the ends or the top of the transformers.

Ventilated dry type transformers usually have their windings terminated within the enclosure of the transformer to either stand-off insulators or bus bar terminals.

Ok, these are the five transformer constructions you are most likely to meet in a substation inside buildings:

- Liquid filled transformers

- Ventilated dry type transformers

- Sealed dry type transformers

- Cast-coil dry type transformers

- Totally enclosed, non-ventilated dry type transformers

1. Liquid filled transformers

Are constructed with the windings encased in a liquid-tight tank filled with insulating liquid.

The liquid provides insulation between the various sections of the windings and between the windings and the tank, and serves as a cooling medium, absorbing heat from the windings and transferring it to the outside of the tank.

To increase the transfer of heat to the air, tanks are provided with cooling fans (to increase the area of the radiating surface) or with external cooling tubes or radiators. The hot liquid circulates through the radiators, transferring the heat picked up in the transformer windings to the radiator and then to the surrounding air.

Fans are sometimes installed to force air over the radiators in order to increase the full load rating by approximately 15% on transformers rated 750-2000 kVA and 25% on transformers rated 2500-10 000 kVA.

IMPORTANT NOTE! It is essential that the liquid in the transformer be maintained, clean, and free from moisture! Moisture can enter the transformer through leaks in the tank covers or when moisture-laden air is drawn into the transformer.

Transformers can draw air into the tanks through breathing action that results from changes in the volume of liquid, and air in the tank that occurs with changes in temperature. Most modern transformer constructions are tightly sealed and do not breathe if they are free from leaks.

Insulating liquid, through the normal aging process, develops a small amount of acid that, if allowed to increase above well-established limits, can cause damage to insulation in the transformer.

Yearly testing to determine the dielectric breakdown voltage of the liquid (a low dielectric test indicates the presence of water or other foreign material) and neutralization number (a high neutralization number indicates the presence of acid in the liquid) by a competent testing laboratory will greatly prolong the life of the transformer.

Liquid samples should be withdrawn under carefully controlled conditions as directed by the group making the liquid test. In some areas, this service is available from the electric utility.

The classification and handling of existing liquid filled transformers with regard to polychlorinated biphenyl (PCB) contamination is subject to strict control by environmental agencies.

It is important that any existing liquid filled transformers that have not been “evaluated” tagged, or otherwise classified be properly handled. Liquid filled transformers, which contain from 50–500 parts per million (ppm) of PCB, have successfully been brought into the 0–50 ppm range, which is within the limits of non-PCB contamination.

Go back to transformer constructions ↑

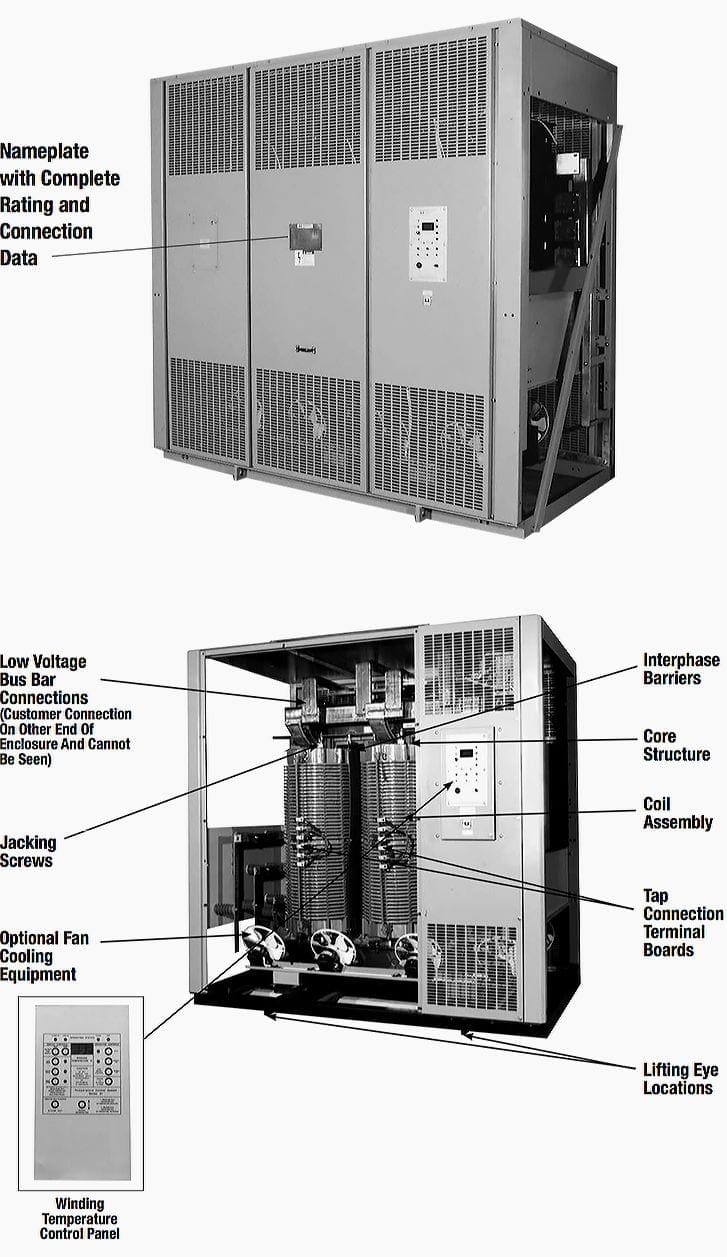

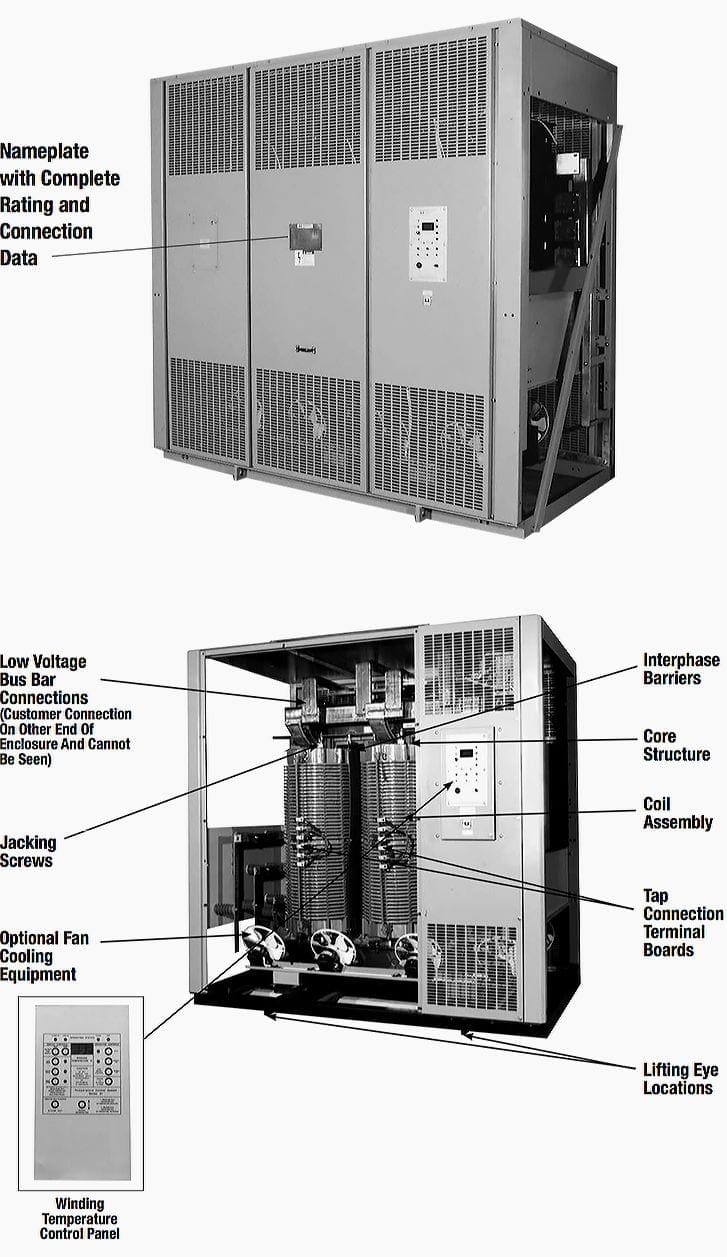

2. Ventilated dry type transformers

Are constructed in much the same manner as liquid filled transformers, except that the insulating liquid is replaced with air, and larger clearances and different insulating materials are used to compensate for the lower dielectric strength of air.

Both ventilated dry type and sealed dry type transformer constructions use a UL component recognized insulation system that is suitable for operation at an ultimate temperature of 220°C. The normal temperature rise of the windings is 150°C by resistance.

If transformers are purchased with a 220°C insulation system, but are rated for full load use at a lower temperature (115°C or 80°C rise), then an improvement in efficiency, overload capability, and life can be expected.

Consideration should also be given to nonlinear harmonic loads, such as SCRs, UPS, rectifiers, and variable speed drive applications, since these higher harmonics can cause appreciably higher eddy and stray loss heating in the windings as well as very high currents in the neutrals of these transformers.

Very often special designs for nonlinear load applications are preferable to just oversizing the unit because of the skin effect at the higher frequencies.

The ventilated dry type transformer is provided with a sheet metal enclosure that surrounds the winding for mechanical protection of the windings and the safety of personnel. Ventilating louvers are installed in the enclosure to permit thermal circulation of air directly over the winding for cooling. Fans are sometimes installed to force air directly over the windings in order to increase the full load rating by approximately 30-40%.

These transformers are gaining acceptance in the 15 kV and 34.5 kV class, and can be built to match the BIL of liquid immersed transformers and with special enclosures for use outdoors. Meggering before energizing is recommended after a lengthy shutdown or lengthy periods when the insulation has been subjected to moisture.

Go back to transformer constructions ↑

3. Sealed dry type transformers

Sealed dry type transformers are constructed in essentially the same way as ventilated dry type transformers. The enclosing tank is sealed and operated under positive pressures. It may be filled with nitrogen or other dielectric gas. Heat is transferred from the winding to the gas within the transformer housing and from there to the tank and to the surrounding air.

The sealed dry type (gas filled) transformer can be installed both outdoors and indoors and in areas where a corrosive or dirty atmosphere would make it impossible to use a ventilated dry type transformer.

Go back to transformer constructions ↑

4. Cast-coil, dry type transformers

Are constructed with primary and secondary windings encapsulated (cast) in reinforced epoxy resin. Because of the cast-coil construction, they are ideal in applications where moisture or airborne contaminants, or both, are a major concern. This type of construction is available with primary voltage ratings through the 34.5 kV class and BIL ratings through 200 kV.

These transformers are ideal alternatives for liquid or gas filled units in indoor or rooftop applications. They may be forced air cooled to increase their self-cooled ratings by 50%.

Go back to transformer constructions ↑

5. Totally enclosed, non-ventilated dry type transformers

Are constructed in essentially the same way as ventilated dry type transformers. The enclosure, while not sealed, contains air, so the units have the same BIL capabilities as ventilated dry type transformers.

These units are available with fan cooling for a minimum 25% increase in capacity.

Go back to transformer constructions ↑

All above described transformer constructions has various temperature measurement equipment and controls for determining the winding temperature and for activating cooling, tripping, or alarm devices. To make sure the ultimate temperature of the insulating system is not exceeded, imbedded detectors should be wound in each low-voltage winding.

Reference // Recommended Practice for Electric Power Systems in Commercial Buildings – IEEE STD 241

Hi. Include the PadMounted transformer for complete the list.

Are you sure that fan cooling for a minimum 25% increase in capacity.is not small ?.

The oil filled transformers you refer to are ONAN (oil filled natural – air natural) these are no longer preferred, due to the high fire risks and the energy companies and designers are now using KNAN (K fluid natural-air natural) the K fluid is greater than 300 deg. C flame point and the best of these is the Midel 7131 which is one of the very few K3 type liquids, its also biodegradable.

Old style transformers can be retro-filled with Midel at a small cost making them safe and more efficient.

One superior dry type transformer technologies is missing in this document: the glassfibre reinforced transformer with resin applied under atmospheric pressure.

It offers excellent voltage withstand, high ratings and flexible characteristics.

Wow! Please how is the fibre optic used in the transformer? and what for?