Power distribution

It should be understood that the generic term ‘underfloor’ applies to products designed for such use but which may well be used in other environments where the protection is appropriate.

Ducts and risers, and within suspended ceilings are typical spaces where parts of so-called underfloor systems may be appropriately used.

There are two main types of such systems:

- Those designed for incorporation into the floor structure itself, such as trunking systems for casting into the screed, etc., and

- Those designed to be installed below false (computer) floors in commercial buildings.

The principles of the two systems are the same but the strength of the construction is different, as is the detailing of the designs. Systems for incorporation into the floor structure itself are customarily of metallic materials, often galvanised steel, and need to be of high mechanical strength to withstand the rigours of building site conditions at first fix stage.

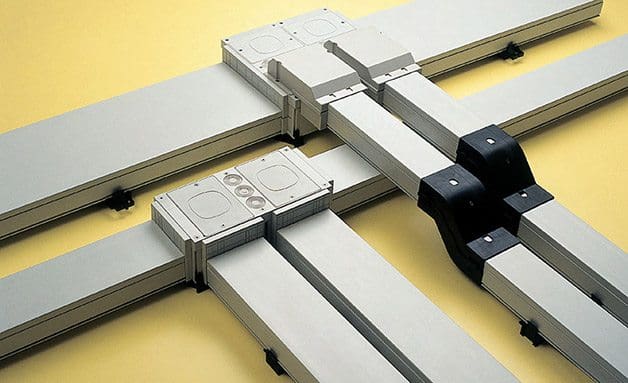

The spine of such systems is usually flat trunking with a top flange intended to eventually become flush with the floor screed. To this, thin but robust covers are fitted. A family of flush outlet boxes is necessary to accommodate the various accessories required, and fittings such as tees and elbows are required to construct the cable runs on site.

As the trunking now invariably needs to be multicompartment, great care is needed to arrange the compartments at junctions and crossovers, and this may be an insurmountable difficulty in some circumstances. Utilisation points can be provided above floor level by the use of power-poles, and conduit can also be teed off the trunking prior to the screeding of the floor.

The more recent developments are all in the area of systems intended for use beneath the raised floor, and laid on top of the structural floor.

This method of construction is referred to as ‘suspended flooring’ or ‘computer flooring’.

Whereas this was traditionally confined to specialist technical areas such as computer rooms and control suites, it is now widely used in commercial buildings due to the flexibility it adds to the building service provisions.

The void so formed between the structural and the functional floor provides flexibility and accessibility of a high order for developing the cable systems throughout the life of the building. Systems for this application are numerous and consist of trunking and conduit similar to conventional products, but with adaptations specifically appropriate for the environment proposed.

Plastics material is very popular, but metallic systems are available if mechanical, or more likely EMC, protection is important in a specific application.

Underfloor installation of a screed-covered duct system

This video illustrates the underfloor installation of a screed-covered EÜK duct system with a GES service outlet. The EÜK underfloor system offers, with the UZD underfloor box, a flexible and robust basis for the provision of power and data technology via the floor.

Usually a number of parallel trunkings are run side by side to provide the segregated circuits, and thus crossovers and junctions become straightforward to understand.

Conduits, usually of the flexible type, can be glanded off to outlets, etc. as required. The trunking is usually fixed to the structural slab floor and access is given by removing the tiles of the suspended floor with specialist tools provided by the flooring contractor. Boxes for accommodating accessories in the floor tiles may be from the flooring specialist or the electrical manufacturer, but as they are connected to the trunking by flexible conduit, compatibility will not become a problem.

Figure 1 shows installed underfloor trunking with feeders to desk sockets or other consumers.

Underfloor voids are useful spaces for the installation of cables that are passing through the area as part of the distribution system of the whole building. Cable tray or basket may be provided for these runs, and all the horizontal legs can be accom- modated in such spaces with great savings to the electrical contractor, once the floor- ing system has been agreed.

This technique, where the cables are loosely bunched by means of cable ties and then laid on the structural floor, has its origins in the control rooms of the broadcasting and telecommunications industries.

The adoption of the technique in the electrical installation industry came about as a result of specialist telecom con- tractors taking work in the construction industry due to their specialist knowledge of specific types of cabling. However, the system is not satisfactory here and will not meet the requirements of regulations and standards (and therefore of insurance companies), regarding a ‘suitable and workman-like’ installation.

Whereas in technical businesses the control and maintenance of such cables can confidently be left in the hands of engineering personnel, in the commercial world access will be made by unskilled persons and the integrity of such cables will be invalidated. The proximity of power distribution cabling then introduces a degree of risk that is not acceptable in the electrical industry.

Resource: Handbook of Electrical Installation Practice – Eur Ing GEOFFREY STOKES

Under-floor cabling has been there for many years. Specially in Control Rooms. The above concept for the under-floor cabling looks very neat and tidy.

Electrical Engineers are doing great jobs. You have well mentioned in your blog about the power distribution by Underfloor Cable system. Both methods of constructing the cables by suspended as well as computer flooring can be appropriately used in the building sites.