Underground residential distribution / URD

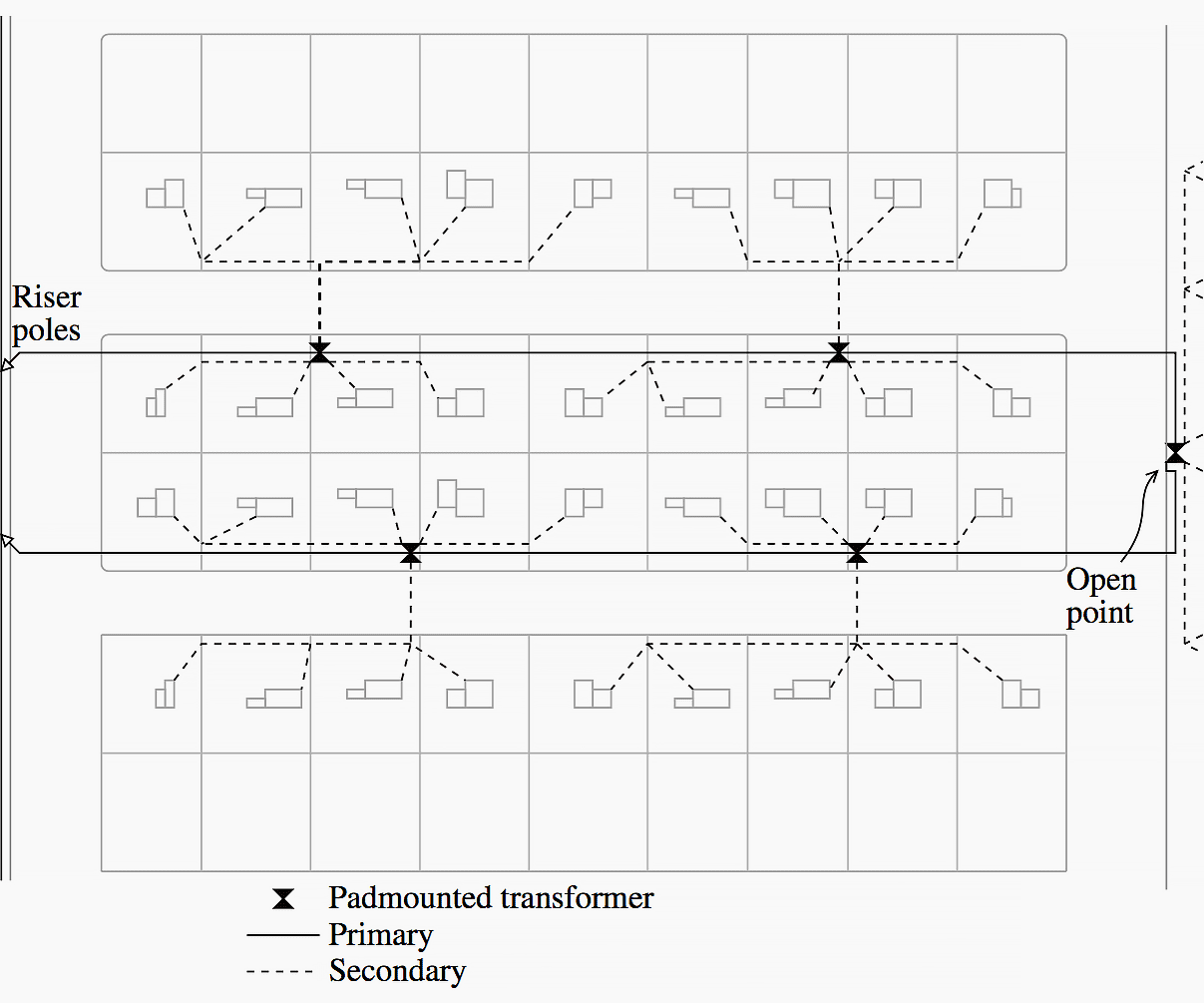

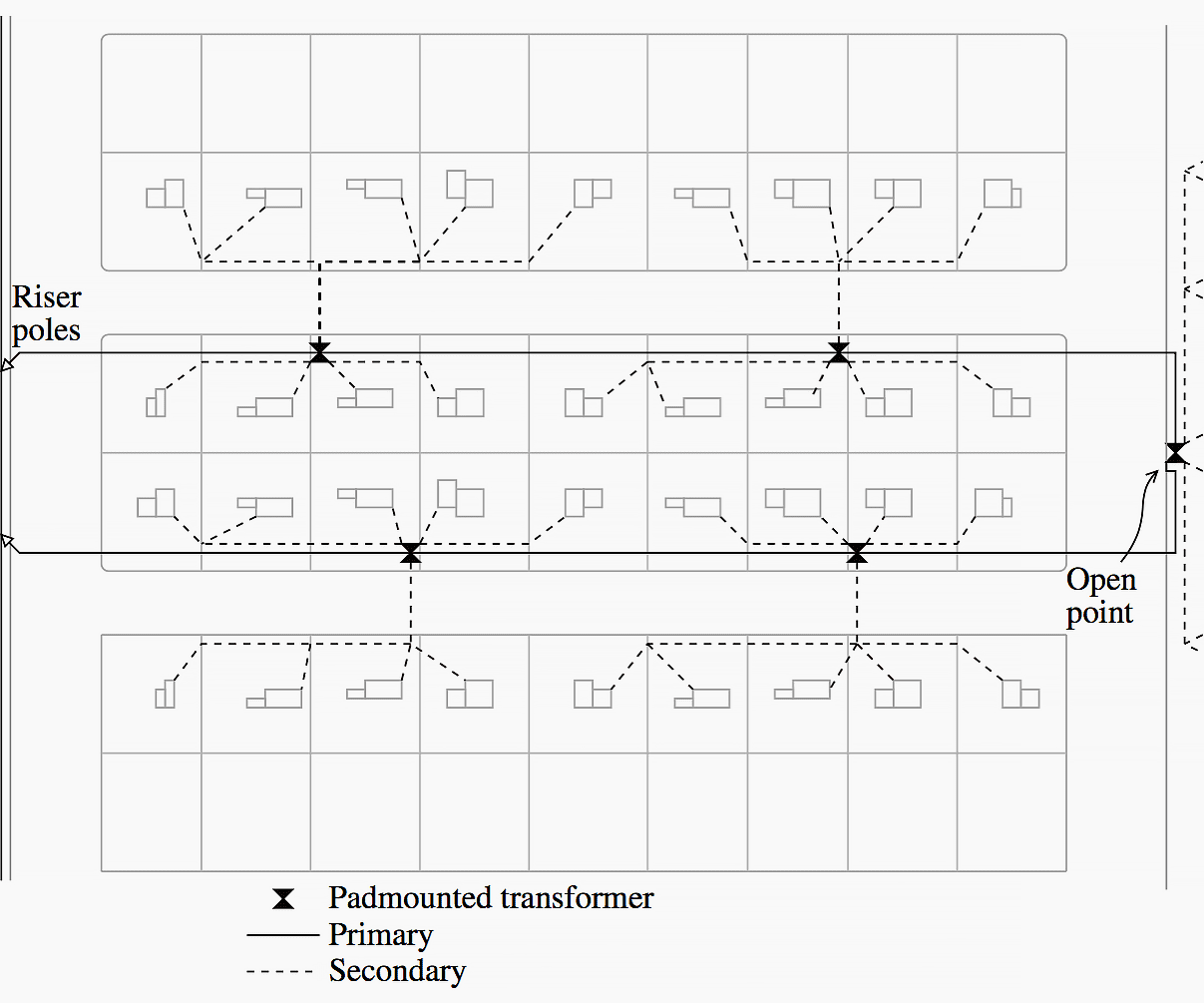

A classic underground residential distribution circuit is an underground circuit in a loop arrangement fed at each end from an overhead circuit (see Figure 1). The loop arrangement allows utilities to restore customers more quickly.

After crews find the faulted section, they can reconfigure the loop and isolate any failed section of cable. This returns power to all customers.

Crews can delay replacing or fixing the cable until a more convenient time or when suitable equipment arrives. Not all URD is configured in a loop. Utilities sometimes use purely radial circuits or circuits with radial taps or branches.

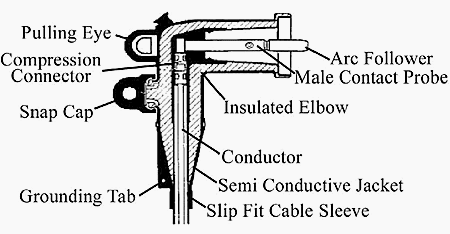

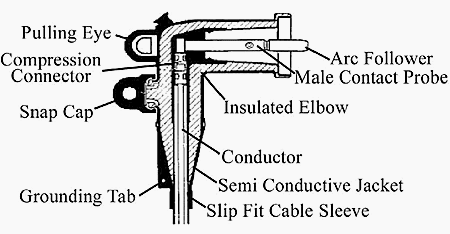

The elbow connectors on the cables (pistol grips) attach to bushings on the transformer to maintain a dead-front — no exposed, energized conductors. To open a section of cable, crews can simply pull an elbow off of the transformer bushing and place it on a parking stand, which is an elbow bushing meant for holding an energized elbow connector.

Elbows and other terminations are available with continuous current ratings of 200 or 600 A (IEEE Std. 386-1995).

Load break elbows are designed to break load. These are only available in 200 A ratings. Without load reak capability, crews should of course only disconnect the elbow if the cable is deenergized.

Elbows normally have a test point where crews can check if the cable is live. Elbows are also tested to withstand ten cycles of fault current, with 200 A elbows tested at 10 kA and 600 A elbows tested at 25 kA (IEEE Std. 386-1995).

The interface between the overhead circuit and the URD circuit is the riser pole. At the riser pole (or a dip pole or simply a dip), cable terminations provide the interface between the insulated cable and the bare overhead conductors. These pothead terminations grade the insulation to prevent excessive electrical stress on the insulation.

Potheads also keep water from entering the cable, which is critical for cable reliability. Also at the riser pole are expulsion fuses, normally in cutouts.

Areas with high short circuit current may also have current limiting fuses. To keep lightning surges from damaging the cable, the riser pole should have arresters right across the pothead with as little lead length as possible.

Underground designs for residential developments expanded dramatically in the 1970s. Political pressure coupled with technology improvements were the driving forces behind underground distribution.

Underground residential distribution has had difficulties, especially high cable failure rates. In the late 1960s and early 1970s, given the durability of plastics, the polyethylene cables installed at that time were thought to have a life of at least 50 years.

In practice, cables failed at a much higher rate than expected, enough so that many utilities had to replace large amounts of this cable.

According to Boucher (1991), 72% of utilities use front lot designs for URD. With easier access and fewer trees and brush to clear, crews can more easily install cables along streets in the front of yards. Customers prefer rear-lot service, which hides padmounted transformers from view.

Back lot placement can ease siting issues and may be more economical if lots share rear property lines. But with rear lot design, utility crews have more difficulty accessing cables and transformers for fault location, sectionalizing, and repair.

Reference // Electric Power Distribution Equipment and Systems by T. A. Short

thank you

In most countries LV and MV distribution networks, mainly in rural areas, are overhead lines. Also HV transmission networks are overhead lines. However overhead lines present some disadvantages:

– Occupy more area.

– Have more visual impact.

– Emanate electric fields that can affect people.

– Are affected by storms, namely lighting phenomena.

By these reasons electrical distribution companies and some electric transmission companies have made an option for underground cables, although it is a more expensive solution. Underground cables present a set of advantages in relation to overheadlines:

– It provides the missing cross border link to urban or near to rural areas

– Underground cables are not susceptible to storm damage

– Underground cables are “invisible”, so no visual intrusion

– Lower losses

– No electric field emanates from underground cables

– Magnetic field from underground can be managed, by use of trefoil arrangement and shielding