Phase failure

A phase failure is an interruption of a single conductor. The motor then continues running with two phases and can suffer damage. The cause is, for example, blown fuse. Small to medium sized motors are mostly stator critical – this means that only the stator can be damaged.

It has to be differentiated between:

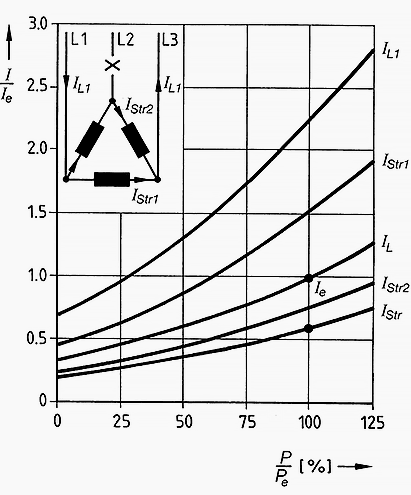

Motors in star connection

These motors are not put at risk by a phase failure. As shown in Figure 1, the currents in the motor windings, during disturbed and undisturbed operation at the failure of a single conductor, equal the currents in the other two. Due to the increasing current, a higher power loss occurs in both live windings.

On the whole, the motor is running cool, since the third cold winding causes a temperature compensation.

In case of an overcurrent, a protective current detector trips in time. Small to medium sized (stator critical) motors in star connection are usually not put at risk during a phase failure.

Where:

- Ie IStr – Currents in the phases and windings in undisturbed operation

- Ie1 IStr1 – Currents in the phases and windings in disturbed operation

Go back to Motor Connections ↑

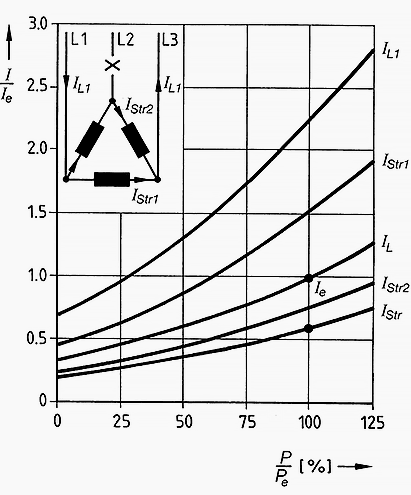

Motors in delta connection

In delta connection, the phase currents in undisturbed operation are lower by a factor 1/√3 than the currents in the windings ISTR = 0.58 In.

This phenomenon occurs because the motor keeps the power transmitted to the shaft practically constant. The absolute current increase in the windings and in both intact phases depends on the load applied.

Where //

- IL IStr – Currents in the phases and windings in undisturbed operation

- IL1 IStr1 IStr2 – Currents in the phases and windings in disturbed operation

Since the currents in the windings are not equal, they do not warm up equally either. Since heat is exchanged between individual windings and between windings and the iron body, the warming up of the stator is proportional to the sum of all losses in all windings.

In general, the following applies for motors with an output of //

Pe ≤ 10kW They do not require a special phase failure protection, as long as the two-phase trip current is ≤ 1.25 Ie . In this case, the warming up is, at the most equal, to the warming up during a symmetrical, three-phase load.

Pe ≥ 10 kW For these motors, a motor protector with phase failure protection or a quick-response electronic protector is recommended. Besides electrical protection, the fast cut-out also contributes to reduced stress on the bearings.

Many companies and electricity company’s factory regulations demand phase-failure sensitive motor protection mainly for bigger drives, or for systems with an increased safety requirement.

For a single phase feed of the stator, the rotor losses are considerably higher compared to a symmetrical feed. This can represent an additional danger, especially for rotor critical motors.

Go back to Motor Connections ↑

Reference // Basics for practical operation – Motor protection by Rockwell Automation

Your question is general (i.e. not specified). Generally, the PLC may be affected or not, depending on the type of fault committed.

3phase motor star delta connection if not corrct posible to damged PLC device

How can one detect a phase failure? And what are the examples

want to be part of PLC Learning

Good Day. Thank you for this article. I found another article on the same topic (below) and I am trying to find out how they calculated the winding current. For example, when there is an open on one of the phases, the line current increases by 1.73. How exactly can we calculate the winding current in the delta connected motor?

http://www.cooperindustries.com/content/dam/public/bussmann/Electrical/Resources/solution-center/motor_circuit_protection/BUS_Ele_Protection_Against_Single-Phasing.pdf

In general, how long can a motor continue run without causing damages when one phase fails? Would it be fine to run for 1 – 2 minutes as an example?

It depends on the insulation class of the motor either A, B, F & H. They have different operating and over-temperature range. This will directly affect how long a motor can operate in one phase fault condition.

The run time would be interrupted by eventual burn out. The speed would be decreased from that of the normal three-phase operational cycle. Great site.

The run time would be interrupted by eventual burn out. The speed would be decreased from that of the normal three-phase operational cycle. Great site.

un motor de 3 fases al fallar una y ponerlo a funcionar en dos fases NO es lo mas indicado..se debe aplicar la técnica del reemplazo de la fase por un condensador, que va depender de la potencia del motor…

There’s an ocean between Europe and USA: phase-failure sensitive protection relay are the standard solution in Europe since 40 years ago (and the only one available on market).

So, three phases motor supplied by two phases still can be continuing running with two phases?

Yes it would still run, but not as fast as when three phase supply is still intact. If let you run the motor during this condition, it would get damage. Performing necessary tests is advise.

To whom it may concern,

The lead picture depicts the brush pattern of a Direct Current machine not a Three Phase Induction Alternating Current machine

See

https://www.google.com.au/search?hl=en&site=imghp&tbm=isch&source=hp&biw=1247&bih=597&q=three+phase+motor&oq=three+pah&gs_l=img.1.3.0i10i24l5.2333.12742.0.17178.20.12.8.0.0.0.335.2724.2-10j1.11.0..2..0…1.1.64.img..1.19.2765.ZxidnFS9SPg

Regards

Derek Bailey

Thanks for noticing Derek, pic replaced with correct one.