Deep understanding the failure

This technical article will try to shed some light on why and how electrical equipment fails and what’s happening before and during the failure of particular substation equipment like switchgear, power transformer, and cable installations. A deep understanding of all mentioned is crucial for preventing substantial electrical hazards and compromising the health and safety of substation operators.

Some statistics say that in a typical year 47% of electrical accidents involved electrically skilled persons and out of a total of 805 electrical accidents 57 were to supervisory and testing staff.

Electricity has a stealth and power which are often disregarded even by electrical engineers and other electrically trained persons. Think of that, it’s important.

1. Causes of Failure

There are two fundamental causes of failure of electrical equipment you should differentiate: mechanical failure or electrical failure of insulation.

1.1 Mechanical causes

The safety of electrical equipment depends to a large extent on sound mechanical design. The majority of circuit breaker failures are mechanical rather than electrical in nature. Typical faults are loose joints leading to overheating or arcing and the existence of voids and contamination in insulation causing arcing and breakdown products.

Where the insulation is bulk oil the products of arcing are themselves highly flammable (acetylene for example) and have often led to explosions.

Fractures may be caused by resonant vibrations of current carrying conductors either from purely mechanical movement or from electromagnetic forces leading to fatigue hardening and subsequent breakage. Where metallic elements are stressed in a corrosive atmosphere (e.g. damp or polluted atmospheres) along with alternating forces, failure may occur at comparatively low stress.

Some steels, which under normal conditions exhibit considerable ductility, will fail at low temperatures by brittle fractures with no ductile deformation.

Mechanical failure of insulators may displace conductors and cause short circuits. Ceramic insulators are brittle but have high strength in compression.

However ceramic insulators are vulnerable where they are used in tension or shearing situations. They are now largely confined to outdoor overhead lines and switchgear where their robust construction makes them less susceptible to mechanical failures although they are then vulnerable to vandalism.

1.2 Breakdown of insulating materials

The electrical breakdown of insulating materials may also occur as follows:

- Mechanically, as by friction or tearing.

- As a result of excessive electrical stress.

- As a result of excessive temperature (and occasionally very low temperature) or temperature cycling. The latter may cause mechanical stresses as a result of differential expansion or contraction.

- Chemical and physical reaction with other materials, e.g. oxidation, contamination or the leaching out of important ingredients which may lead to de-plasticisation, i.e. they become brittle. The ingress of water is a very common contamination leading to `treeing’ and eventual electrical breakdown.

Failure is rarely the result of inadequate electrical breakdown strength where reasonably pure materials are used.

The insulation performance of most commercially used materials is now well documented and standard testing procedures have been established.

2. Substation equipment

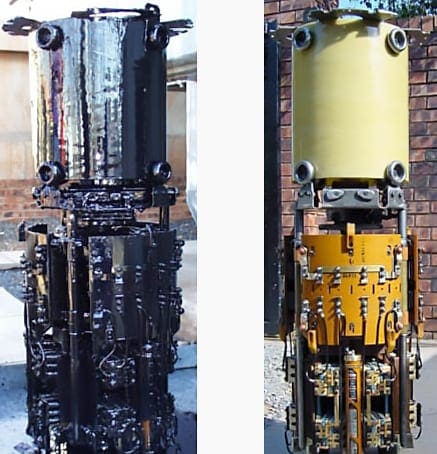

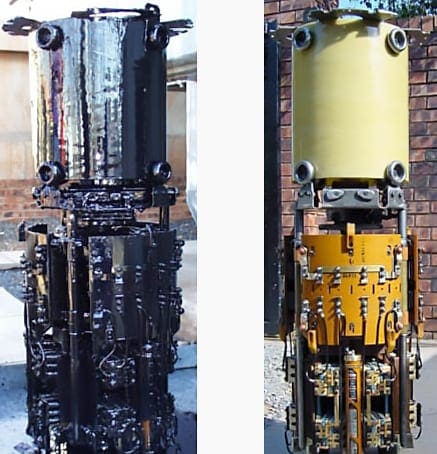

2.1 Switchgear

Hazards associated with switchgear failure include fire, explosion and electric shock. There is a particular risk to the technical staff who require to operate high voltage switchgear and to conduct testing and maintenance on this equipment.

Unfortunately oil circuit breakers and fuse switches have been the cause of many serious accidents and fatalities have not been rare. Some of the most expensive fire losses have also been caused by switchgear.

The causes of high-voltage switchgear failures are typically as follows:

- Poor maintenance leading to contamination of insulation and loose connections etc.

- Incorrect or inappropriate use of test equipment on live equipment.

- Unrestricted repeated operations of oil circuit breakers (OCBs) leading to breakdown of the oil insulation and/or to contact collapses.

- Hesitant operation of manually closed switches onto faulted circuits leading to panic opening on fault and the consequent fault arc drawn at the contacts of a non-rated switch.

- Failures of PTs (potential transformers, often referred to as VTs or voltage transformers) and failures of CTs (current transformers).

2.2 Transformers

Fires and explosions in oil-immersed power transformers have been less common than in oil-immersed switchgear and the immediate results are, on the whole, less damaging.

However, because of the large amount of oil which may be released and ignited, oil-immersed transformers are potentially at least as dangerous and the consequences in terms of loss of power availability and pollution can be considerable.

Many incidents are generally associated with automatic tap-changing gear, while bushing failures, flashover and arcing at the transformer top, etc. (including some lightning damage) cause about the same number of incidents.

Major transformer failures are comparatively rare events.

The main dangers are the spread of fire by the release of a very large volume of burning oil and the emission of clouds of black smoke but there may be secondary hazards such as plant being stopped by damage to cables and protection, control and alarm equipment even when the fire itself was not initially very large.

Typical failures and their causes are described below.

2.2.1 Lightning and voltage transients

These may cause external flashover of bushing insulations which may shatter or split oil-filled insulators, causing fires. If the voltage surge reaches a transformer winding it may cause a flashover above the oil and damage the winding insulation.

2.2.2 Internal flashover above oil

This can be caused by voltage transients as described above but there are other causes which are more easily eliminated. These are arcing caused by fractured conductors, sparking at loose connections, and badly made joints which provide ionisation above the oil level.

Hot joints and connections are also suspected causes.

2.2.3 Interturn faults

Whatever the cause such faults are likely to develop slowly. The volts per turn are normally quite low (say 5±20 V for transformers below 2 MVA) and will not sustain continuous arcing until a number of turns become involved but this may not apply where, in modern transformers, coils and turns are interleaved without spacers to improve surge voltage distribution.

Overheating can be caused by short-circuited turns. Failures may go undetected by conventional protective relays as there is likely to be no significant change in through current.

However some interturn faults can be detected by certain forms of monitoring and testing.

2.2.4 Failure of the insulation of the magnetic circuit

Such failure, e.g. of core frame, or clamping bolts, or between laminations, can allow parasitic eddy currents and local heating. The former may cause sparking and the evolution of arc gases. Such faults do not lead to immediate danger but contribute to the deterioration of insulation and oil.

Other faults which occur from time to time are due to poor hygiene and untidiness during manufacture and maintenance. Nuts, bolts, cut-off ends of wire and even spanners have been found wedged between windings.

These can cause local stress concentration and heating with possible mechanical damage to insulation.

2.2.5 Overloading and ‘through’ faults

These will overheat the windings and cause cumulative damage to the insulation. They may not cause immediate danger unless they persist but the life of the transformer will be shortened.

There are advantages in using sealed transformer tanks. Experience indicates that in the absence of air (oxygen) the oil deteriorates much more slowly and less maintenance is necessary.

Also, a sealed tank, unless it has a separate expansion chamber or conservator at the top, cannot be fitted with a Buchholz relay and it may be impossible to give full protection against slowly developing faults.

A sealed tank should therefore be provided with a bursting disc or similar device as a major fault between phases or to earth, caused by lightning, fractured conductors, loose connections, etc., may otherwise cause the tank to rupture or the lid to be sprung before differential or overcurrent relays have time to operate the circuit-breakers.

Such faults are rare, and it may be that there are situations where the risk can be accepted, but this would not be the case for very large transformers, transformers in occupied buildings, or high fire-risk situations.

2.3 Cables and installations

Traditionally, high voltage distribution cables, if they were buried in the ground, were impregnated paper (tape) insulated, lead covered, steel wire armoured and served (i.e. protected with a sheath of material resembling bitumen impregnated sacking) and frequently further protected by ceramic tiles a few inches above the cable.

Modern cables comprise plastic materials with metal extruded or wire armouring. Cables often have a life measured in many decades and many cables of early style construction may be found in use, particularly on public electricity distribution systems.

Medium voltage (400/230 V) distribution cables were steel tape armoured but sometimes tough rubber or similar sheaths were used in ducts. Such cables pose a very low fire risk.

Modern cables mainly use plastic insulation. The main hazards are:

- Burst cable boxes at transformers, switchgear and other joints. Link, or street mains disconnecting, boxes which use the traditional bitumen insulation have been the subject of many incidents of failure, mainly due to voids in the bitumen, water ingress and to loose connections.

- Puncture by pneumatic road drills which causes short circuits and a shower of sparks, but which is often more alarming than dangerous because the sheath and armouring provide an efficient earth-return path.There have been incidents of serious burn injuries too however, the severity of the arcing being dependent on the power fault level of the transformers feeding onto that particular circuit. In cities these fault levels are often very high.

- The spread of fire in ducts or tunnels.

The evolution of clouds of black smoke from cable oil is a serious hazard because it hampers effective fire extinguishing operations, contaminates buildings and may result in the need for extensive cleaning and renovation work.

There is then a substantial liberation of hydrogen chloride, which may corrode sensitive electrical equipment, e.g. in telephone exchanges and computer departments, and steel reinforcement bars in concrete.

Important cable tunnels should be provided with fire detection and monitoring equipment and possibly fixed fire extinguishing installations.

The relative positions of power, telecommunication, control, and alarm and safety circuits must be considered, to ensure that power short circuits and fires do not damage safety circuits.

Cable tunnels are perhaps more vulnerable to fortuitous ‘external’ fires than to short circuits, etc.

Under-floor ducts are subject to flooding and the entry of rubbish, flammable liquids and vapours. Overhead distribution busbars along a line of machines are frequently used, particularly where the position of machines may be changed at short notice when there is a change of product or method.

The conductors are usually, but not invariably, covered with insulation, except at fixed points where provision is made for tapping off, and the whole assembly of busbars is enclosed in suspended metal trunking with provision for ‘plug and socket’ attachments or spur switch and fuse combinations.

The construction must be considered in relation to possible damage by cranes, forklift trucks, etc., and the entry of water from a leaking roof or sprinkler systems.

It is preferable to make the connections to individual machines by cables with a flexible outer metallic screen, pliable armoured cable or by flexible conduit.

Sources:

- Electrical Engineer’s Reference Book by M. A. Laughton CEng., FIEE and D. J. Warne CEng., FIEE

Interesting article and to the point. I work in HV substations and we are currently investigating a recent arc flash at an 11 kV RMU in where a cable tester left a shorting wire connected at the cable terminals. It completely carbonized the whole termination chamber with metal soot, as well as the busbar chamber. The unit will have to be be replaced.

well worth the first time there,s lot to learn

You can use thermals imagine camera . Before it happens you can identify over heated place and correct them.

Sir, thanks for very informative article.i m operator at 132 kv substation in a semi govt; company in Pakistan. On 25/08/2019 at 1900 hrs when I leave 11 kv control /switch room after kwh units noting on daily log sheet as per schedule,a heavy blast occurred in 11kv control pannel and fire traveling to other pannels on same 11kv busbar towards 11 kv incoming.All protection failled, tried to open related 132 kv power transformer circuit breaker but in vain,so opened 132 kv line breakers sources on local mode by their tripping coils pushing.All 11kv pannels burnt.oh God,I escaped in a sudden .now all control room system is new installed.controlling power transformer damaged also.

Very nice and valuable article for all Electrical engineers working in Sub station and dealing with HV/ ehv equipment.

Thank you for the basic information provided relative to these subjects – much appreciatd!

PLG at LGI Interstellar. C.T., R.S.A.

Educative highlights.