Planning concept for power supply

When a planning concept for power supply is developed, it is not only imperative to observe standards and regulations, it is also important to discuss and clarify economic and technical interrelations (cables and/or busbar trunking systems depending on situations).

The rating and selection of electric equipment, such as distribution boards and transformers, must be performed in such a way that an optimum result for the power system as a whole is kept in mind rather than focusing on individual components.

The most important is that all components must be sufficiently rated to withstand normal operating conditions as well as fault conditions.

Further important aspects to be considered for the creation of an energy concept are:

- Type, use and shape of the building (e.g. high-rise/low-rise building, multi-storey building)

- Load centers and possible power transmission routes and locations for transformers and main distribution boards

- Building-related connection values according to specific area loads that correspond to the building’s type of use

- Statutory provisions and conditions imposed by building authorities

- Requirements of the power distribution network operator

The following requirements are the main points of interest //

- Easy and transparent planning

- Long service life

- High availability

- Low fire load

- Flexible adaptation to changes in the building

Most applications suggest the use of suitable busbar trunking systems to meet these requirements.

For this reason, engineering companies increasingly prefer busbar trunking to cable installation for power transmission and distribution. The most common busbar trunking systems ratings are from 25 A to 6,300 A.

Planning Notes

Considering the complexity of modern building projects, transparency and flexibility of power distribution are indispensable requirements. In industry, the focus is on continuous supply of energy as an essential prerequisite for multi-shift production.

The five main advantages of busbar trunking systems are //

- Straightforward network configuration

- Low space requirements

- Easy retrofitting in case of changes of locations and consumer loads

- High short-circuit strength and low fire load

- Increased planning security

Power transmission

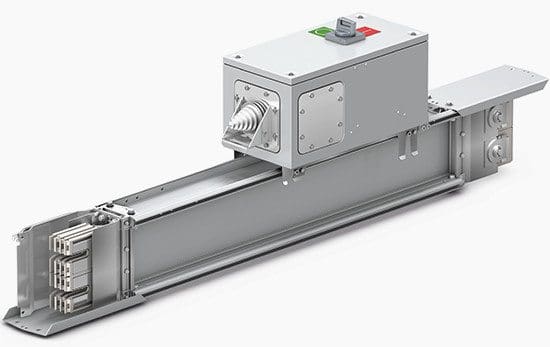

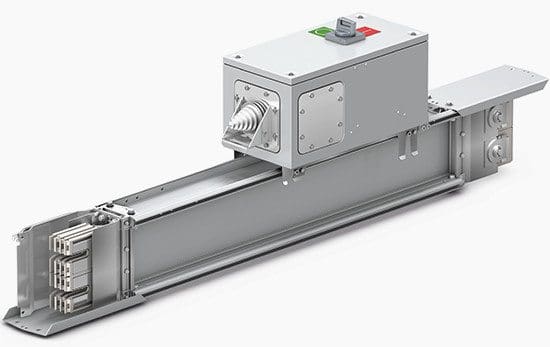

Power from the transformer to the low voltage switchgear is transmitted by suitable components in the busbar trunking system. These components are installed between transformer and main distribution board, then branching to sub-distribution systems.

Trunking units without tap-off points are used for power transmission. These are available in standard lengths. Besides the standard lengths, the customer can also choose a specific length from various length ranges to suit individual constructive requirements.

Power distribution

Power distribution is the main area of application for busbar trunking systems. This means that electricity cannot just be tapped from a permanently fixed point as with a cable installation. Tapping points can be varied and changed as desired within the entire power distribution system.

In order to tap electricity, you just have plug a tap-off unit on the busbar at the tap-off point. This way a variable distribution system is created for linear and / or area-wide, distributed power supply.

Tap-off points are provided on either or just one side on the straight trunking units. For each busbar trunking system, a wide range of tap-off units is available for the connection of equipment and electricity supply.

Table 1 – Cable / Busbar comparison

| Characteristic | Cables | Busbar |

| Planning, calculation | High determination and calculation expense, the consumer locations must be fixed | Flexible consumer locations, only the total load is required for the planning |

| Expansions, changes | High expense, interruptions to operation, calculation, risk of damage to the insulation | Low expense as the tap-off units are hot pluggable |

| Space requirements | More space required because of bending radiuses and the spacing required between parallel cables | Compact directional changes and fittings |

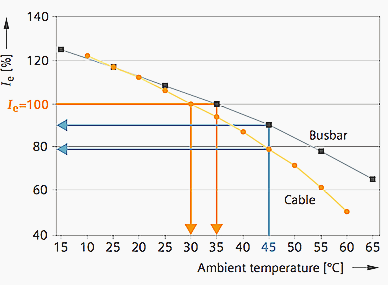

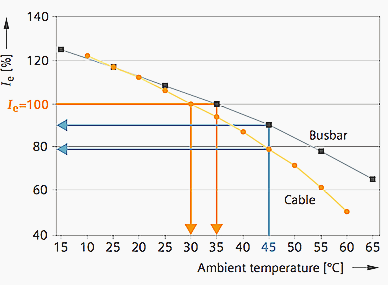

| Temperature responses and derating | Limits depend on the laying method and cable accumulation. The derating factor must be determined / calculated | Design verified switchgear assembly, limits from manufacturer’s catalogue |

| Free from halogen | PVC cables are not free from halogen. Halogen-free cables are very expensive | Principally free from halogen |

| Fire load | Fire load with PVC cable is up to 10 times greater, with PE cable up to 30 times greater than with busbars | Very low, see manufacturer’s catalogue |

| Design verified switchgear assembly | The operational safety depends on the version | Tested system, non-interchangeable assembly |

Few more on why busbar trunking systems //

Easier when it comes to planning

Easy to plan, quick to install and flexible to use. Busbar trunking systems bring energy economically into any building. The power distribution system can be precisely planned from the total load rating and the type and number of loads.

Clarity is assured by the line-shaped network topology with regularly arranged load tap-offs. Using standardized sizes, all applications can be implemented quickly and in minimum space.

Quicker when it comes to installing

Benefits during installation. Two-man assembly of busbar trunking systems saves time and money compared to the costly cable installation method. Installation errors are practically ruled out by the safe and user-guided connection technology.

No special tools are required.

SIVACON 8PS LI busbar trunking systems (VIDEO)

Canalis Range (VIDEO)

Reference // Switchgear and Substations by SIEMENS

It’s useful and interesting thanks

You’re welcome, Osama. I’m glad you liked the article.

Dear Sir,

It is realy good topic and valuable info have been included. i have an issue with contractor, we have an extension project of existing switchgear and the contractor mentioned that he can not use busduct because existing switchgear panel is not extendable! so he suggest to use cable at the outgoing breaker to link the new panel with existing. the length of cable is arround 10m max. please advise?

the volt level is 11KV and 400V

Hi Sir! Thanks for sharing your valuable knowledge.

We have 2000kVA step down transformer 6.6kV/400V in our power station. We have busbar trunking on LV side of transformer that connects LV winding to distribution board. Last time (july 2019) when we carried out insulation resistance test on Busbar, we found very low IR values (2M ohms @500V applied voltage). The area is very humid and very near to beach. We checked thoroughly but couldn’t find anything abnormal. What could be the reason?

The transformer is located outside and distribution board is located in side air conditioned switch gear.

This busbar trunking video’s are given good knowledge about trunking .. thanks

I have done a similar project, trust me its the best .

Any one did the comparison between cable installation and busbar trunking system regarding heat absorption; as the client asking to study the effect of both solution regarding HVAC system; as it will be installed in shopping mall to feed shopping areas

THIS IS REALLY A NICE COLLECTION. THANKS A LOT TO BROTHER EVARD.

Good information. If any interest in custom IR window solutions for use on busbar joints and tap boxes, please contact me at http://www.iriss.com. We have developed solutions for several OEM’s already to allow IR inspection – especially well accepted in critical power applications like Data Centers and Hospitals. Also, we do low cost wireless temperature monitoring called Delta T that can be easily retrofitted to existing busbar systems or designed into new OEM busbar offers.

Dear Sir, the photo “Busbar trunking power transmission” is our photo made in Italy in a government office building. Pls correct it.

Image caption corrected. Thank you for notice!

We have very bad experiences using bus duct in our plant, whether it is non segregation or sandwich type. The problem was condensation or water ingress lead to short circuit. The trunking bus connecting outdoor transformer to switchgear inside the substation. Even though the IP rating is IP55, equipped with space heater and with additional enclosure believe the problem because our harsh environment (high humidity and ambient temperature, located in coastal tropical country). We are thinking to replace the trunking system with one that more reliable or using the cable..Any thoughts?

Dear Ryan, we are Graziadio and we produce since 1959 busbars in Italy. For this kind of problem we have the Isolsbarra system with IP66 or Ip68 and with zero problem of condensation as every single phase is insulated.

We have big experience in this kind of projects with no problems.

I am ready to help you to find a proper solution as the busbars are sure the best choice instead of cables.

I have Manufacturing facility in Qatar under construction, it has 2 transformers each 1600 kv, my plan was only to use cables BUT now I am thinking of bus bar for advantages of relocating the machines and might cheaper, i need someone to work witb me hand by hand to implement this solution, we have very harsh environent here very high humidity very very hot in summer. Regard. Ahmed

This…

http://www.preedcrete.co.uk via BKS busbar systems.

I read your Comments on Bus Bar SC due to condensation. Looks that Mylar Wrap Conductors are used. I observed this kind of Problem at the Elbow where the water gets accumulated. It was suggested to use Resin Cast Bus bar at that portion. Also with this the Problem of SC was sorted out. I have 45 years Experience in Switchgear in which 17 years in Siemens India, 10 years in in Bus Way & rest in Panel.

Good Information on Bus bar System. Bus bar is a Cheaper Solution of Power Transmission when compared with Cables. I have worked in Siemens & understood on Panels & Bus bar Trunking, then got a chance to work with Power Bar Gulf which is the Leading LV/MV Bus bar Trunking Manufacturer in the Region of Gulf, to work in Bus bat Trunking Manufacturing & gained a Good Knowledge.