Content

- Introduction to Dams

- Dam Characteristics

- Embankment Dams

- Concrete Dams

- Other Dam types

- Missouri River Dam in South Dakota (VIDEO)

Introduction to Dams

Dams and weirs are primarily intended to divert the river flow into the water conveyance system leading to the powerhouse. Dams also produce additional head and provide storage capacity. We’ll talk about dams and its types in this technical article.

The choice of dam type depends largely on local topographical and geotechnical conditions.

For instance if sound rock is not available within reasonable excavation depth, rigid structures such, as concrete dams are difficult. Conversely, for narrow valleys, it can be difficult to find space for separate spillways, and concrete dams can be the natural choice with their inherent possibilities to integrate spillways etc in the dam body.

In the Nordic countries the ice age has left us with wide and open valleys and moraine material in abundance. Not surprisingly the vast majority of dams are embankment dams with a central core of moraine.

South of the Alps natural clays suitable for dam core are not in abundance and the topography in many locations favour concrete dams.

These parameters can be important, because of the complicated administrative procedures often associated with the construction of large dams.

Dam Characteristics

World wide, embankment dams are the more common partly due to the following characteristics, which they possess:

- Can be adapted to a wide range of foundation conditions.

- Construction uses natural materials, which can often be found locally, limiting needs for long transportation.

- The construction process can be continuous and highly mechanized.

- The design is extremely flexible in accommodating different fill materials.

Disadvantages with embankment dams are that they are sensitive to overtopping and leakage, and erosion in the dam body and its foundation.

There is a higher mortality rate among embankment dams as compared to concrete dams.

Concrete dams on the other hand have drawbacks that correspond to the pros of the embankment dams:

- Require certain conditions withrespect to the foundations.

- Require processing of natural materials for aggregate at the site, hauling of large quantities of cement and has a labour intensive and discontinuous construction process, leading to large unit costs.

- They are suitable for most ranges of topography that is for wide and narrow valleys, provided that foundation conditions are right.

- They are not very sensitive to over topping.

- A spillway can be placed at the crest, and if required over the entire length of the dam.

- Chambers or galleries for drainage, tubing and ancillary works can readily be housed within the dam body.

- Powerhouses can be placed right at the top of the dam.

The development of the Concrete Faced RockfillDam (CFRD) neutralizes many of the drawbacks with core-type embankments. In particular, sensitivity to leakage and erosion is reduced, and dependence of good core material is removed.

The development of the Roller Compacted Concrete Dams (RCC-dams) introduces a continuous, highly mechanised construction process and low unit costs. New large dams are almost always CFRD and RCC designs.

1. Embankment Dams

Homogeneous dams

These dams are used for low embankments (<4m) and often as secondary dams. For dam safety reasons, some type of drainage is almost always provided.

Zoned embankment dams

These are used for dam heights from 4m and up. Constructions are extremely sensitive to the engineering design and construction, and it is therefore vital to engage highly skilled consultants and contractors require experienced site-supervision engineers.

Critical components of these dams are the core, the transition zones (filters) surrounding the core and drainage capacity of the dam toe (see figure 1).

Embankments dams with membrane

The membranes can be of different types and be located either at the upstream front of the embankment or vertically in the centre of the embankment.

Membranes can be made from concrete (as in the CFRD), asphalt (Norwegian type) or in the form of a geomembrane on the upstream slope.

Embankment dams are often categorised according to the main fill material, for example, rock-fill dams, or earth-fill dams.

2. Concrete Dams

Generally, concrete dams are categorized according to how they function statically, and fall into one of the following groups.

Gravity dams

These are dependent on their own mass for stability. Their cross-section is basically triangular in order to provide adequate stability and stress distribution across the foundation plane.

The upper part is normally rectangular in order to provide adequate crest width for installation and transportation.

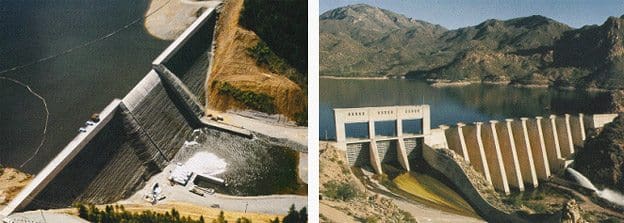

Design issues include stability analysis (sliding and overturning), stress control, temperature control during construction to avoid cracking, control of uplift pressures under the dam, etc. In photo 1 a gravity dam constructed of RCC (left photo) is shown. Note the characteristic stepped downstream slope.

Buttress dams

These dams consist of a continuous upstream face that is supported by buttresses at regular intervals.

The upstream face is normally divided into vertical sections by dilatation joints, each section being supported by a buttress.

Cross-sections are similar to those of gravitation dams. In colder climates, the upstream face can be susceptible to freezing of the water contained in the concrete, damaging the concrete. For this reason buttress dams in such locations are often covered along the downstream contour of the buttresses in order to provide climate control.

The right-hand photo in photo 1 shows an example of a buttress dam. Note that the spillway is also a buttress type structure.

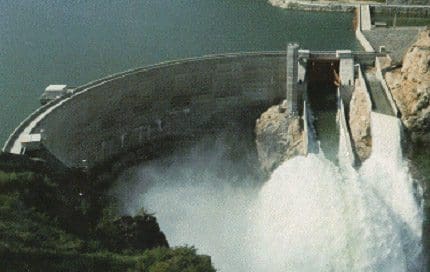

Arch and Cupola dams

These dams function structurally as horizontally laid out arches that transfer the water pressure on the upstream face into the abutments rather than into the foundation.

Arch dams can be designed with a constant radius over the dam height, or with varying radii (Cupola dams). Arch dams with a constant radius have a vertical and “straight” cross-section.

These dams will be subject to considerable vertical strainforces since the deformation of the dam will tend to be greatest in the vertical centre of the dam. This requires that the dam be heavily reinforced to avoid cracking with accompanying leakage.

The arch and cupola dams are structurally efficient and greatly reduce the required volume of concrete.

They require, however, a narrow valley topography and strong foundation rock in the abutments. In photo 2 an example of an arch dam is shown, and in figure 2 the typical geometry for single curvature arch dams versus double curvature cupola dams is displayed.

3. Other Dam types

Another type of concrete dam is the spillway dam, which can be gated or ungated.

A gated dam with large spillway openings compared to the dam height is often designed to function as a buttress dam, whereas higher spillway dams with relatively small spillway openings normally are designed to function as a gravity dam.

An ungated spillway dam is often referred to as a weir for lower dam heights.

An old dam type still prevailing is the masonry dam. This dam was prevalent during the early days of industrialization, utilizing the building techniques present at that time.

The masonry structure functioned as the load bearing structure and water tightness was provided by either vertical timber sheeting on the upstream face or by filling impervious soils upstream of the masonry structure.

Missouri River Dam in South Dakota (VIDEO)

Resource: Guide on How to Develop a Small Hydropower Plant (European Small Hydropower Association – ESHA)

So many things I have to learn about hydropower from this site.Thanks Edvard.

Thank you Zaw!

Thanks Anirudh, very kind of you!

Best site for Electrical Engineers!!!