Why energy efficient? Let’s see.

Many energy saving actions can encourage specifiers and engineers to look closely at the savings which can be made by specifying an energy efficient version of a particular component.

This technical article presents the case for taking the important step and looking at the overall benefit of specifying energy efficient options throughout the system, looking at the motor and cabling together, and if appropriate, the local power transformer.

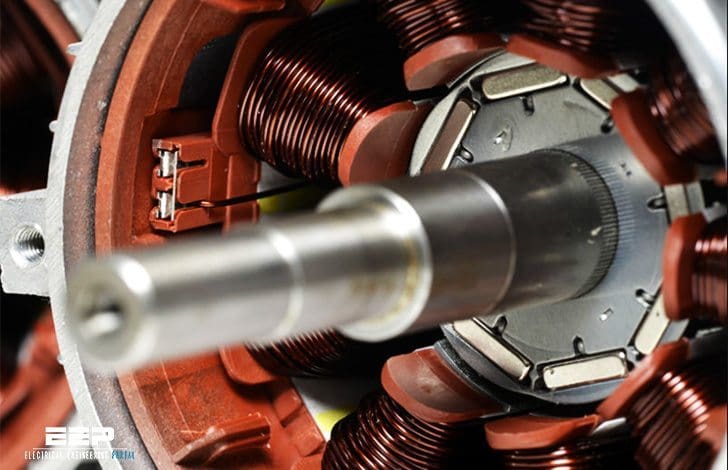

1. The Motor

As an example, consider a ventilation fan motor, working full time, at 100 metres from the distribution panel.

| Rating kW | % Load | Output Power kW | Duty hours/year |

| 7.5 | 87 | 6.525 | 8,760 |

Typical Motor parameters:

| Efficiency | Output Power | Input Power | Annual Consumption | Current per phase | |

| Comparison | [%] | [kW] | [kW] | [kWh] | [A] |

| Standard | 87 | 6.525 | 7.50 | 65,700 | 9.84 |

| Energy efficient | 90 | 6.525 | 7.25 | 63,510 | 9.51 |

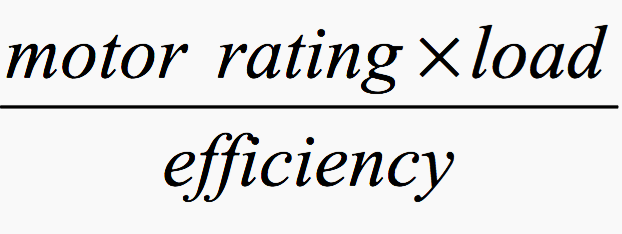

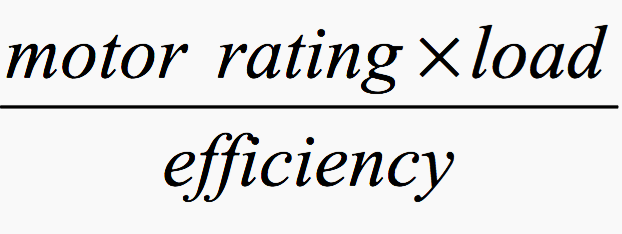

The input power is given by the following formula:

At a unit cost of £0.0443 per unit, the annual saving is £97.02, while the incremental cost of the energy-efficient motor would be about £95.

Go back to energy efficient options ↑

The Cable

A conductor cross-section of 1.5 mm2 would be considered adequate – from a thermal rating point of view – to carry this current (< 10A). Such a cable would have a resistance of 25 milliohms per metre.

The power loss in the cable is:

pL = I2 × R

The reduction in power loss in the cable due to the use of an energy efficient motor is:

pD = (I12 – I22) × R

pD = (9.842 – 9.512) × 25 × 10-3 × 100

pD = 5.796 × 2.5 = 14.49 W

Energy saved per year = 127 kWh

For a 1.5 mm2 cable supplying an energy efficient motor the power loss is:

= 9.512 × 25 × 10-3 x 100 = 226.1 W per phase, or 678.3 W total for all three phases.

Using, say, 10 mm2 cable would reduce the total loss to 103.1 W, giving an annual saving of

575.2 × 8,760 = 5,037 kWh

At a unit price of £0.0443 per unit, the annual saving would be £223.14. Since the cost of installation will not be significantly higher than for the smaller cable, the only additional cost is the purchase cost of the cable.

This table shows the power saving achieved so far:

| For 6.525 kW output power | Standard motor | Energy efficient motor |

| 1.5 mm2 cable [kW] | 10 mm2 cable [kW] | |

| Input power | 8.178 | 7.353 |

| Overall efficiency [%] | 80 | 89 |

The overall annual power saving is 7,227 kWh, or £320.16.

Go back to energy efficient options ↑

3. The Transformer

There are dozen of factors which should be considered when selecting local transformers (core losses, load losses, winding material, etc.). By careful selection of the motor and cabling we have already reduced the input power by 10%, and consequently the attributable transformer load loss by 21%.

Using the standard and low loss transformers from Table 1 and assuming that it is running at 80% load, the incremental loss associated with a 1 kW load for each transformer can be estimated at 24.4 W and 21.25 W respectively.

| Typical RES (10% TDR) | Typical Industry user | Typical RES (5% TDR) | |

| Loss capitalisation values per kilowatt | £3,000/£625 | £3,988/£814 | £3,750/£780 |

| Standard loss alternative | |||

| No-load loss 0.735 kW | £2,205.00 | £2,931.18 | £2,756.25 |

| Load loss 4.8 kW | £3,000.00 | £3,907.20 | £3,744.00 |

| Price | £5,000.00 | £5,000.00 | £5,000.00 |

| Totals | £10,205.50 | £11,838.38 | £11,500.25 |

| Low loss alternative | |||

| No-load loss 0.38 kW | £1,140.00 | £1,515.44 | £1,425.00 |

| Load loss 4.08 kW | £2,550.00 | £3,321.12 | £3,182.40 |

| Price | £6,690.00 | £6,690.00 | £6,690.00 |

| Totals | £10,380.00 | £11,526.56 | £11,297.40 |

| Amorphous steel alternative | |||

| No-load loss 0.145 kW | £435.00 | £578.26 | £543.75 |

| Load loss 4.77 kW | £2,981.25 | £3,882.78 | £3,720.60 |

| Price | £7,315.00 | £7,315.00 | £7,315.00 |

| Totals | £10,731.25 | £11,776.04 | £11,579.35 |

TDR – Test discount rate

REC – Regional Electricity Companies

For the incremental load of the motor, the additional losses are 195.2 W for the standard and 170 W for the low loss transformer, so that the low loss transformer saves a further 221 kWh per annum. The additional cost of selecting a low loss transformer is equivalent to £5.37 per kW of rating (based on a 315 kW unit), so that attributable to the motor load (remembering that the overall loading is 80%) is £53.60.

| Input power [kW] | ||

| For 6.525 kW output power | Standard motor 1.5 mm2 cable standard transformer (kW) | Energy efficient motor 10 mm2 cable low loss transformer (kW) |

| Input power to motor | 7.500 | 7.250 |

| Input power to cable | 8.178 | 7.353 |

| – plus incremental transformer loss | 8.373 | 7.523 |

| Annual consumption | 73,347 kWh | 65,901 kWh |

The overall saving is 7,446 kWh per year, equivalent to £329.85 per year (at £0.0443 per unit).

It must be remembered that the selection of more efficient downstream components, including cabling, reduces losses in other components upstream.

Go back to energy efficient options ↑

Reference // Electrical Energy Efficiency by Copper Development Association

Copyright Notice

This technical article is protected by U.S. and international copyright laws. Reproduction and distribution of PDF version of this technical article to websites such as Linkedin, Scribd, Facebook and others without written permission of the sponsor is illegal and strictly prohibited.© EEP-Electrical Engineering Portal.

Related electrical guides & articles

Premium Membership

Edvard Csanyi

Hi, I'm an electrical engineer, programmer and founder of EEP - Electrical Engineering Portal. I worked twelve years at Schneider Electric in the position of technical support for low- and medium-voltage projects and the design of busbar trunking systems.I'm highly specialized in the design of LV/MV switchgear and low-voltage, high-power busbar trunking (<6300A) in substations, commercial buildings and industry facilities. I'm also a professional in AutoCAD programming.

Profile: Edvard Csanyi

Hello EEP personnel’s, am very happy I have you as my electrical engineering followers, I will be glad to be part of this platform and get a lot of electrical articles. Thank you

Its nothing about specification parameters of the equipment. Its general theory and calculations with low loss and related results. If possible please try to provide some information if standard and energy efficient equipment are manufactured by the manufacturer or if there is any standard code (national or international) providing difference for them.