High Voltage Station – 3 Main Processes

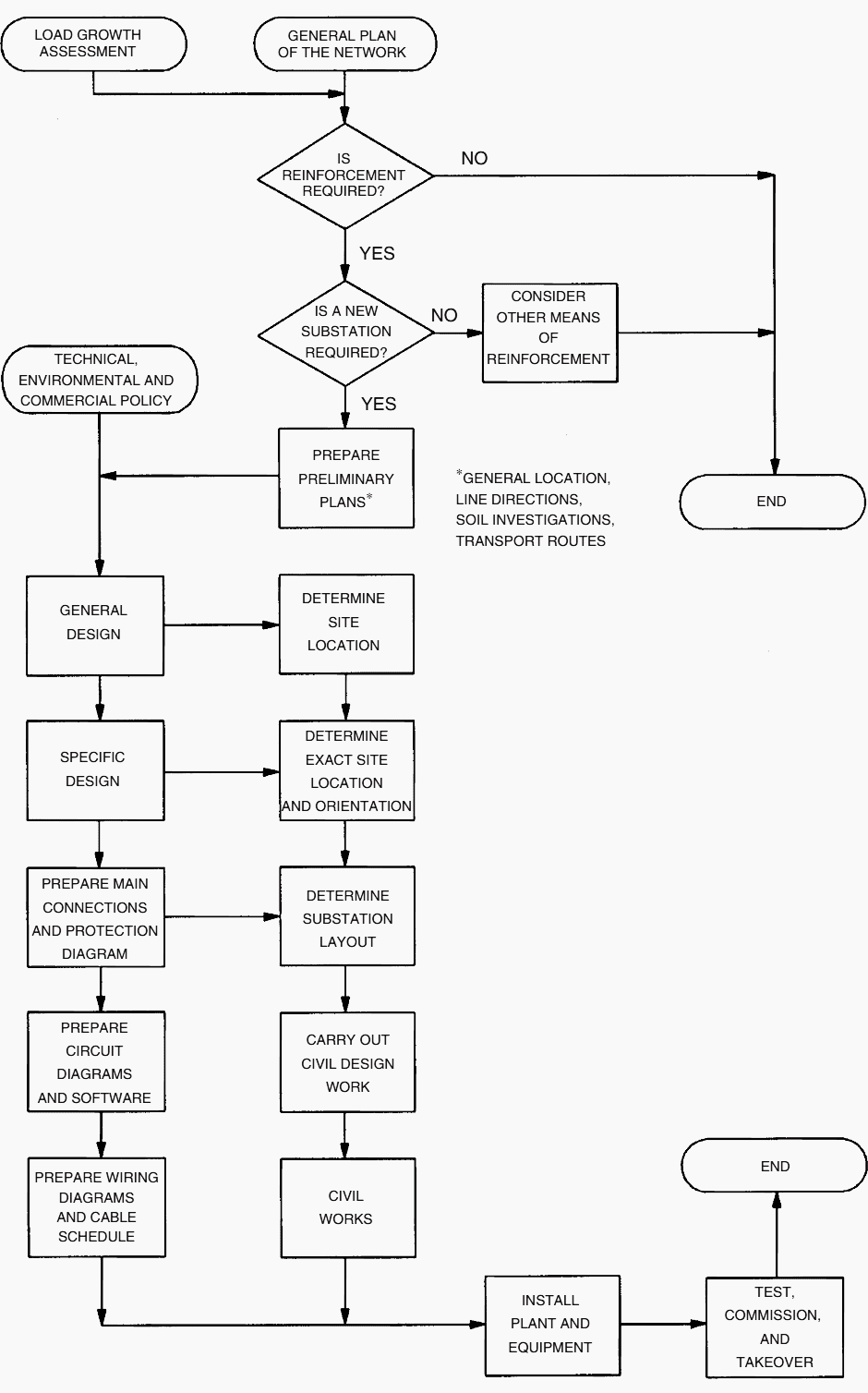

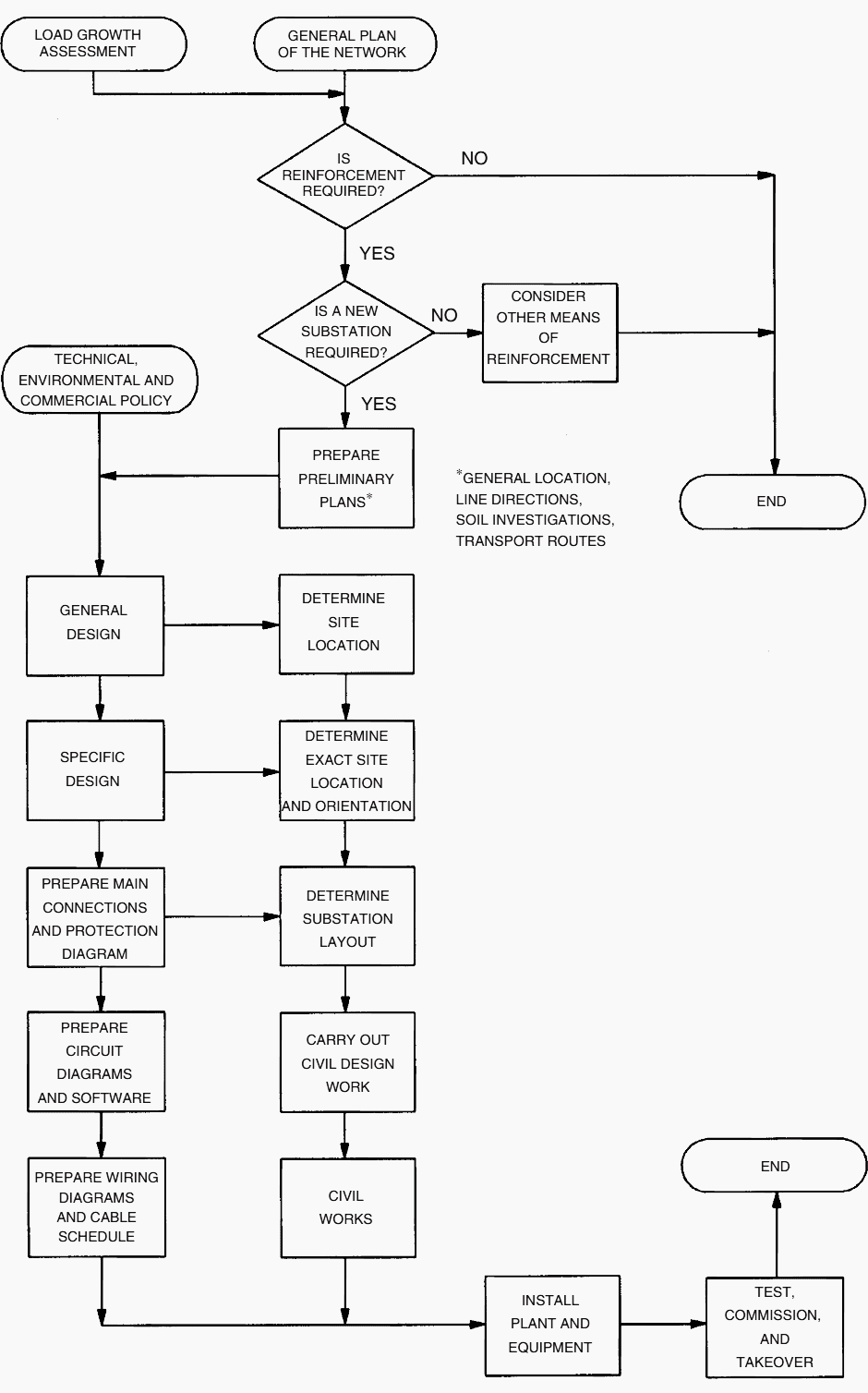

Having selected the right site location for high voltage station, the design construction and commissioning process would broadly follow the steps shown in Figure 1. Recent trends in utilities have been toward sourcing design and construction of HV stations through competitive bidding process to ensure capital efficiency and labor productivity.

Now, let’s start discussing the three main processes:

1. HV Station Design

Now the final detailed designs can be developed along with all the drawings necessary for construction. The electrical equipment and all the other materials can now be ordered and detailed schedules for all disciplines negotiated. Final manpower forecasts must be developed and coordinated with other business units.

Once the designs are completed and the drawings published, the remaining permits can be obtained.

The following can be used as a guide for various design elements:

Basic Layout

- Stage development diagram

- Bus configuration to meet single line requirements

- Location of major equipment and steel structures based on single line diagram

- General concept of HV station

- Electrical and safety clearances

- Ultimate stage

Design

- Site Preparation – Drainage and erosion, earth work, roads and access, and fencing

- Foundations – Soils, concrete design, and pile design

- Structures – Materials, finishes, and corrosion control

- Buildings

- Control, metering, relaying, and annunciation buildings — types such as masonry, prefabricated, etc.

- Metalclad switchgear buildings

- GIS buildings

- Mechanical Systems

- HVAC

- Sound enclosure ventilation

- Metalclad switchgear or GIS buildings ventilation

- Fire detection and protection

- Oil sensing and spill prevention

- Buswork

- Rigid buses

- Strain conductors – swing, bundle collapse

- Ampacity

- Connections

- Phase spacing

- Short circuit forces

- Insulation – Basic impulse level and switching impulse level

- HV Station Insulators

- Porcelain post type insulators

- Resistance graded insulators

- Polymeric post insulators

- Subtation insulator hardware

- Selection of subtation insulator – TR – ANSI and CSA standard

- Pollution of insulators – pollution levels and selection of leakage distance

- Suspension Insulators

- Characteristics

- Porcelain suspension insulators

- Polymeric suspension insulators

- Suspension insulators hardware

- Selection of suspension insulators

- Pollution of insulators – pollution levels and selection of leakage distance

- Clearances

- Electrical clearances

- Safety clearances

- Overvoltages

- Atmospheric and switching overvoltages

- Overvoltage protection – pipe and rod gaps, surge arresters

- Atmospheric overvoltage protection – lightning protection (skywires, lightning rods)

- Grounding

- Function of grounding system

- Step, touch, mesh and transferred voltages

- Allowable limits of body current

- Allowable limits of step and touch voltages

- Soil resistivity

- General design guidelines

- Neutral Systems

- Background of power system grounding

- Three and four wire systems

- HV and LV neutral systems

- Design of neutral systems

- HV Station Security

- Physical security

- Electronic security

Go back to HV station processes ↑

2. HV Station Construction

With permits in hand and drawings published, the construction of the substation can begin. Site logistics and housekeeping can have a significant impact on the acceptance of the facility.

Parking for construction personnel, traffic routing, truck activity, trailers, fencing, and mud and dirt control along with trash and noise can be major irritations for neighbors, so attention to these details is essential for achieving community acceptance.

Go back to HV station processes ↑

3. HV Station Commissioning

Once construction is complete, testing of various systems can commence and all punch-list items addressed. To avoid duplication of testing, it is recommended to develop an inspection, testing and acceptance plan.

Elements of inspection, testing and acceptance plan include:

- Factory acceptance tests (FAT)

- Product verification plan (PVP)

- Site delivery acceptance test (SDAT)

- Site acceptance tests (SAT)

Final tests of the completed substation in a partially energized environment to determine acceptability and conformance to customer requirements under conditions as close as possible to normal operation conditions will finalize the in-service tests and turn-over to operations.

Public relations personnel can make the residents and community leaders aware that the project is complete and the station can be made functional and turned over to the operating staff.

Go back to HV station processes ↑

Reference: The Electric Power Engineering Handbook by Grigsby, L.L (Get it from Amazon)

Is there much work available in this space for subcontractors?

this is a great site ..

merci

Hi,

I would say there is one major item missing, that is the specification and purchase of main circuit apparatus and auxiliary power systems.