NEC Code 430.22 (Size of Cable for Single Motor)

Size of Cable for Branch circuit which has Single Motor connection is 125% of Motor Full Load Current Capacity.

Example

What is the minimum rating in amperes for Cables supplying 1 No of 5 hp, 415-volt, 3-phase motor at 0.8 Power Factor.

- Full-load currents for 5 hp = 7Amp.

- Min Capacity of Cable= (7X125%) =8.75 Amp.

NEC Code 430.6 (A) (Size of Cable for Group of Motors or Elect.Load)

Cables or Feeder which is supplying more than one motors other load(s), shall have an ampacity not less than 125 % of the full-load current rating of the highest rated motor plus the sum of the full-load current ratings of all the other motors in the group, as determined by 430.6(A).

For Calculating minimum Ampere Capacity of Main feeder and Cable is 125% of Highest Full Load Current + Sum of Full Load Current of remaining Motors.

Example

What is the minimum rating in amperes for Cables supplying 1 No of 5 hp, 415-volt, 3-phase motor at 0.8 Power Factor , 1 No of 10 hp, 415-volt, 3-phase motor at 0.8 Power Factor, 1 No of 15 hp, 415-volt, 3-phase motor at 0.8 Power Factor and 1 No of 5hp, 230-volt, single-phase motor at 0.8 Power Factor?

- Full-load currents for 5 hp = 7Amp

- Full-load currents for 10 hp = 13Amp

- Full-load currents for 15 hp = 19Amp

- Full-load currents for 10 hp (1 Ph) = 21Amp

- Here Capacity wise Large Motor is 15 Hp but Highest Full Load current is 21Amp of 5hp Single Phase Motor so 125% of Highest Full Load current is 21X125%=26.25Amp

- Min Capacity of Cable= (26.25+7+13+19) =65.25 Amp.

NEC Code 430.24 (Size of Cable for Group of Motors or Electrical Load)

As specified in 430.24, conductors supplying two or more motors must have an ampacity not less than 125 % of the full-load current rating of the highest rated motor + the sum of the full-load current ratings of all the other motors in the group or on the same phase.

It may not be necessary to include all the motors into the calculation. It is permissible to balance the motors as evenly as possible between phases before performing motor-load calculations.

Example

What is the minimum rating in amperes for conductors supplying 1No of 10 hp, 415-volt, 3-phase motor at 0.8 P.F and 3 No of 3 hp, 230-volt, single-phase motors at 0.8 P.F.

- The full-load current for a 10 hp, 415-volt, 3-phase motor is 13 amperes.

- The Full-load current for single-phase 3 hp motors is 12 amperes.

- Here for Load Balancing one Single Phase Motor is connected on R Phase Second in B Phase and third is in Y Phase.

- Because the motors are balanced between phases, the full-load current on each phase is 25 amperes (13 + 12 = 25).

- Here multiply 13 amperes by 125 %=(13 × 125% = 16.25 Amp). Add to this value the full-load currents of the other motor on the same phase (16.25 + 12 = 28.25 Amp).

- The minimum rating in amperes for conductors supplying these motors is 28 amperes.

NEC 430/32 Size of Overload Protection for Motor

Overload protection (Heater or Thermal cut out protection) would be a device that thermally protects a given motor from damage due to heat when loaded too heavy with work.

All continuous duty motors rated more than 1HP must have some type of an approved overload device.

An overload shall be installed on each conductor that controls the running of the motor rated more than one horsepower. NEC 430/37 plus the grounded leg of a three phase grounded system must contain an overload also. This Grounded leg of a three phase system is the only time you may install an overload or over – current device on a grounded conductor that is supplying a motor.

To Find the motor running overload protection size that is required, you must multiply the F.L.C. (full load current) with the minimum or the maximum percentage ratings as follows;

Maximum Overload

- Maximum overload = F.L.C. (full load current of a motor) X allowable % of the maximum setting of an overload,

- 130% for motors, found in NEC Article 430/34.

- Increase of 5% allowed if the marked temperature rise is not over 40 degrees or the marked service factor is not less than 1.15.

Minimum Overload

- Minimum Overload = F.L.C. (full load current of a motor) X allowable % of the minimum setting of an overload,

- 115% for motors found in NEC Article 430/32/B/1.

- Increase of 10% allowed to 125% if the marked temperature rise is not over 40 degrees or the marked service factor is not less than 1.15.

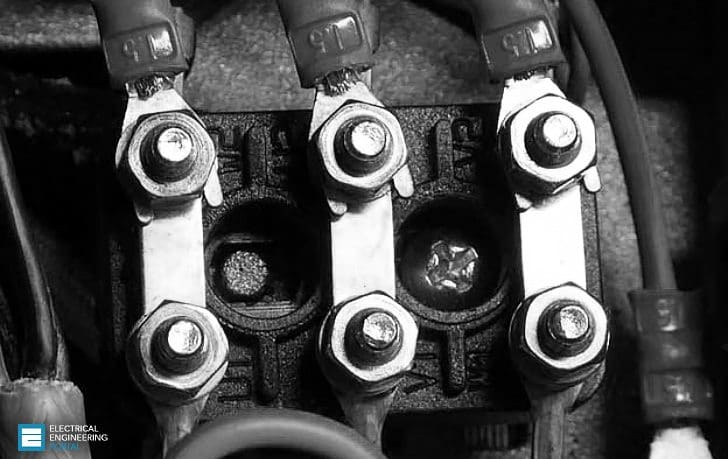

I AM A ELECTRICAL ING

Dear sir,

I have a issue with consulting officer regarding motor termination without terminal block it’s acceptable use nut and bolt if there is any standard accept this type termination can you please send me your guidance to my email shafeekkummiyil@gmail.com thank you.

Dear Sir,

I have an issue with cable sizing. I have a motor of pump to be installed at site. The motor power rate is 55kW/3 phase/380Volt. The total cable length is about 130m. What is the minimum cable size to be used?

Thanks and best regards,

Rachmad Buchari

it usefull

If someone follows the NEC and IEC cables ampacity and is selecting c.b. following this regulations. Can we say that cable is safe whatever the voltage drop is. In otherwords, can we say that the cable would never heat up as much as we are respecting the table? For example if a 6mm cable is protected with 30amps c.b. can we say that even if the voltage drop is 20% it would not cause heat up for cable???

the role of starting current of the motor and the fault level in motor supply cable sizing may also please be explained.

Hello Edvard/Jignesh

Thanks for this posting. It is useful. Are there any articles on selection of cables, breakers,protection etc. for branch circuits, feeder circuits, main Transformer for residential buildings, hotels, hospitals etc. based on NEC guidelines.