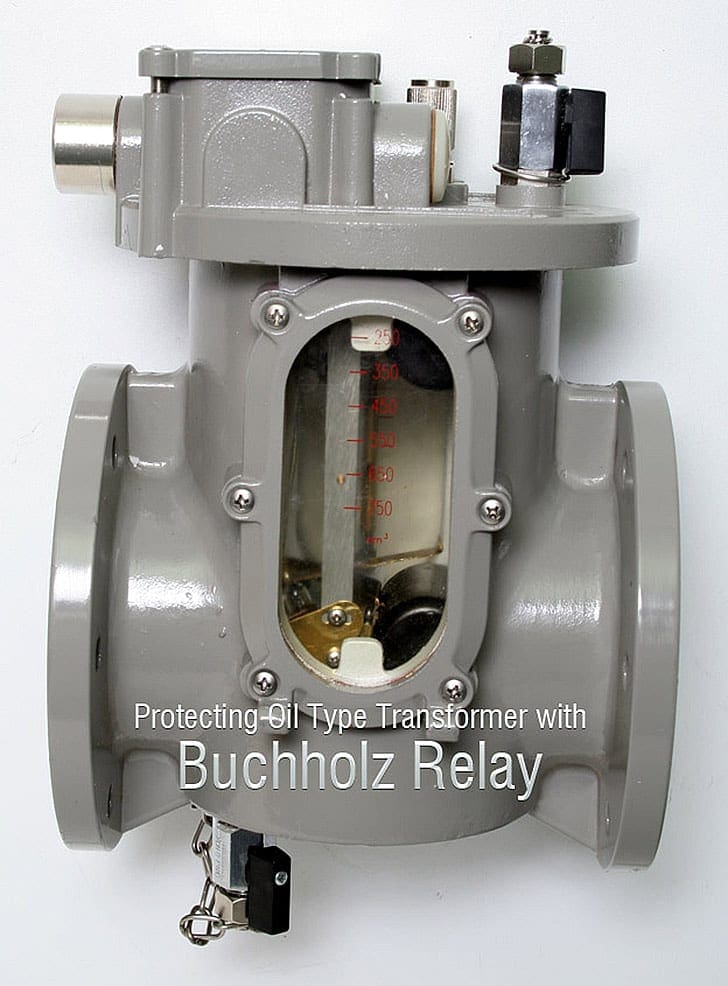

Introduction to Buchholz Relay

Buchholz relay is a gas-actuated relay installed in oil immersed transformers for protection against all kinds of faults. Named afteri ts inventor mr. Max Buchholz (1875–1956) in 1921, relay is used to produce an alarm in case of incipient (i.e.slow-developing) faults in the transformer and to disconnect the transformer from the supply in the event of severe internal faults.

It is usually installed in the pipe connecting the conservator to the main tank. It is a universal practice to use Buchholz relays on all such oil immersed transformers having ratings in excess of 750 kVA. The Buchholz relay is a protective rely for equipment immersed in oil for insulating and cooling purpose.

The Buchholz relay operates even on very slight faults which are just in process of developing, so that greater damage may be prevented.

Protection Range

The relay is particularly effective in case of:

- Falling oil level owing to leaks

- Short circuited core laminations

- Short – circuits between phases

- Broken-down core bolt insulation

- Earth faults

- Bad contacts

- Puncture of bushing insulators inside tank

- Overheating of some part of the windings

In the event of a fault, oil or insulations decomposes by heat, producing gas or developing an impulse oil flow. To detect these phenomena, a Buchholz relay is installed.

Construction and technical characteristics

| Position | Description |

| 1-2 | Release terminals |

| 3-4 | Alarm terminals |

| 5 | Earth terminal |

| 6 | Breather cock |

| 7 | Valve of pneumatic test |

| 8 | Mechanical test of the alarm/release circuit |

| 9 | Cable gland |

| 10 | Drain plug |

Casing Non porous weatherproof compact casting of light aluminium alloy painted.

Cover Non porous weatherproof compact casting of light aluminium alloy painted. On the cover are located : the terminal box, the valve of pneumatic test, the breather cock, the button for mechanical test of alarm and trip circuits.

Inspection windows Special tempered glass with graduated scale in cm3.

Contacts – They can be mercury switches or magnetic actuated switches (reed contacts). On request its possible to supply change-over switches.

Switches characteristics

Rated voltage: 24 ÷ 250V AC or DC

Rated current: 0,5 A (10000 tests)

Breaking capacity: 2 A AC (cos = 0,4 ÷ 25% – 50Hz) 2A DC (T = L / R = 40 msec).

Mechanical protection degree IP 54

Insulation 2000V 50Hz between terminals and earth for a 60 seconds time.

Working temperature Oil temperature range: – 25 / +115°C.

Vibration test (in normal operative conditions)

Oscillation amplitude: 2mm

Time diagram:

0Hz ÷ 100Hz 30 sec.

100Hz (200 vibrations/sec.) 60 sec.

100Hz ÷ 0Hz. 30 sec.

Contacts capacity to withstand vibrations

Mercury sw: 150 horizontal vibrations/sec. (75Hz) first signals of closing contacts 120 vertical vibrations/sec. (75Hz) first signals of closing contacts.

Magnetic sw: 200 horizontal vibrations/sec. (100Hz) no one signal of closing contacts 200 vertical vibrations/sec. (100Hz) no one signal of closing contacts.

Function of Buchholz relay

In the following the operation of a Buchholz relay is explained using the example of a double-float Buchholz relay. The relay is built in the connecting pipe between the transformer tank and the conservator. During normal operation it is filled completely with insulating liquid.

Due to buoyancy the floats are at their top position. If a fault occurs inside the transformer, the Buchholz relay responds as follows:

Gas accumulation

Fault: Free gas is available in the insulating liquid.

Response: The gas in the liquid moves upwards, accumulates in the Buchholz relay and displaces the insulating liquid level. The moving float actuates a switch contact (magnet contact tube). An alarm signal is tripped. The lower float is not affected as from a certain gas volume the gas flows through a piping to the conservator.

Insulating liquid loss

Fault: Insulating liquid loss due to leakage.

Response: As the liquid level falls the top float moves downward. An alarm is tripped. If the liquid loss continues, conservator and piping as well as the Buchholz relay will be emptied. As the liquid level falls, the lower float moves downward. The moving float actuates a switch contact so that the transformer is disconnected.

Insulating liquid flow

Fault: A spontaneous incident generates a pressure wave moving in the direction of the conservator.

Response: The liquid flow reaches a damper arranged in the liquid flow. If the flow rate exceeds the operating threshold of the damper, the latter moves in flow direction. Due to this movement a switch contact is actuated so that the transformer is disconnected.

The upper and lower switching system form a functional unit in the single-float Buchholz relay. In case of a fault, the single-float Buchholz relay normally isolates the transformer immediately from the mains system.

Wiring Diagrams

Standard Wiring Diagram

Mounting Sketch

Advantage

1. It is the simplest form of transformer protection.

2.It detects the incipient faults at a stage much earlier than is possible withother forms of protection.

Disadvantage

1. It can only be used with oil immersed transformers equipped withconservator tanks.

2. The device can detect only faults below oil level in the transformer. Therefore, separate protection is needed for connecting cables.

References:

- Terman – Buchholz relay broshure

- EMB Elektromotoren und Gerätebau Barleben GmbH – Transformer Protection Relays (Buchholz Principle)

how on puncher of insulation core ,this bucholz will work?

What happens if the buchholz relay is connected in the opposite direction?

Explained beautifully

Didn’t mention that what type of gases generated in transformer during faults and which kind of gas operates buchoz relay.

Very Nice and well explained

Thank you Alozie.

good article easy to understand working of relay & how it protects the transformer . thank you very much Sir

Thank you for inform and I follow up knowledge of electrical engineering from your site

There are some problems in HV / lv bushing, or in HV Winding, / lv Winding, resion for gas development in main tank of t/f,

very insightful im frm zimbabwe

Dear All,

Have you anyone has faced problem of Buchholz relay maloperation ?

It seems due to one of its internal connection (normally open contact connection) out of 3 get earthed & showing zero IR value.

Relay is MR/CEDASPE make

Regards,

Sanjay

one sentence is incorrect The relay neither (should be either) gives a warning signal or disconnects the endangered equipment.

Brilliant.

Very right !!!

Dear All ,

I am facing frequent gas accumulation in one of my 56.25 MVA Transformer 13KV/11 Voltage Level of Schneider Make.

Transformer is Charged from 132 KV Side & present condition is no Load (Running Load is approximate 150 KV . Gas is accumulated in bucholz after every 24 hrs , I am not able to find the reason. Pl help me in findout reson of this problem

very good article easy to understand working of buchholz relay & how it protects the transformer . thank you

dear team,

super it’s very nice & easily understand

Nice and easy concepts about protection of power transformer. I also written my own think about protection of transformer. You can read it and just tell me how it is ? http://electricallife.com/transformer-protection/

Very helpful & well written article on all you need to know about the Buchholz relay.Thanks EEP

Hi

Is it possible to damage the floats and switching mechanisms when injecting gas into a buchholz relay through the petcock.