Continued from first part: Medium Voltage Switchgear (1) – Basics of Switching Devices

3. Selection of Switching Devices

Switching devices are selected both according to their ratings and according to the switching duties to be performed, which also includes the switching rates.

3.1 Selection according to ratings

The system conditions, that is, the properties of the primary circuit, determine the required parameters.

The most important of these are:

Rated voltage

The upper limit of the system voltage the device is designed for. Because all high voltage switching devices are zero-current interrupters, except for some for fuses the system voltage is the most important dimensioning criterion.

Rated insulation level

The dielectric strength from phase to earth, between phases and across the open contact gap, or across the isolating distance. The dielectric strength is the capability of an electrical component to withstand all voltages with a specific time sequence up to the magnitude of the corresponding withstand voltages.

These can be operating voltages or higher frequency voltages caused by switching operations, earth faults (internal overvoltages) or lightning strikes (external overvoltages). The dielectric strength is verified by a lightning impulse withstand voltage test with the standard impulse wave of 1.2/50μs and a power frequency withstand voltage test (50Hz/1min).

Rated normal current

The current that the main circuit of a device can continuously carry under defined conditions. The temperature increase of components – especially contacts must not exceed defined values.

Permissible temperature increases always refer to the ambient air temperature. If a device is mounted in an enclosure, it may be advisable to load it below its full rated current, depending on the quality of heat dissipation.

Rated peak withstand current

The peak value of the major loop of the short circuit current during a compensation process after the beginning of the current flow, which the device can carry in closed state.

Rated short circuit making current

The peak value of the making current in case of short circuit at the terminals of the switching device. This stress is greater than that of the rated peak withstand current, because dynamic forces may work against the contact movement.

Rated breaking current

The load breaking current in normal operation. For devices with full breaking capacity and without a critical current range, this value is not relevant.

Rated short circuit breaking current

The root – mean – square value of the breaking current in case of short circuit at the terminals of the switching device.

3.2 Selection according to endurance and switching rates

If several devices satisfy the electrical requirements and no additional criteria have to be taken into account, the required switching rate can be used as an additional selection criterion.

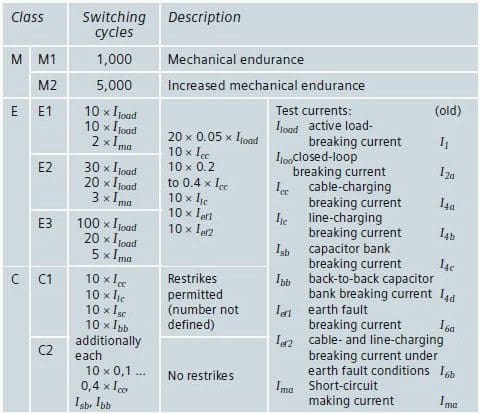

Table 1 through table 5 show the endurance of the switching devices, providing a recommendation for their appropriate use. The respective device standards distinguish between classes of mechanical (M) and electrical (E) endurance, whereby they can also be used together on the same switching device.

Switches:

Standard IEC 62271 – 103/VDE 0671 – 103 only specifies classes for the so called general-purpose switches. There are also ‘special switches’ and ‘switches for limited applications’.

Disconnectors up to 52kV may only switch negligible currents up to 500mA (e.g., voltage transformer), or larger currents only when there is an insignificant voltage difference (e.g., during busbar transfer when the bus coupler is closed).

General–purpose switches

General-purpose switches must be able to break different types of operating currents (load currents, ring currents, currents of unloaded transformers, charging currents of unloaded cables and overhead lines), as well as to make on short circuit currents.

General-purpose switches that are intended for use in systems with isolated neutral or with earth fault compensation must also be able to switch under earth fault conditions.

SF6 (Sulfur hexafluoride) switches

SF6 switches are appropriate when the switching rate is not more than once a month. These switches are usually classified as E3 with regard to their electrical endurance.

Air-break or hard-gas switches

Air-break or hard-gas switches are appropriate when the switching rate is not more than once a year. These switches are simpler and usually belong to the E1 class. There are also E2 versions available.

Vacuum switches

The switching capacity of vacuum switches is significantly higher than that of the M2/E2 classes. Vacuum switches are used for special tasks: mostly in industrial power supply systems, or when the switching rate is at least once a week.

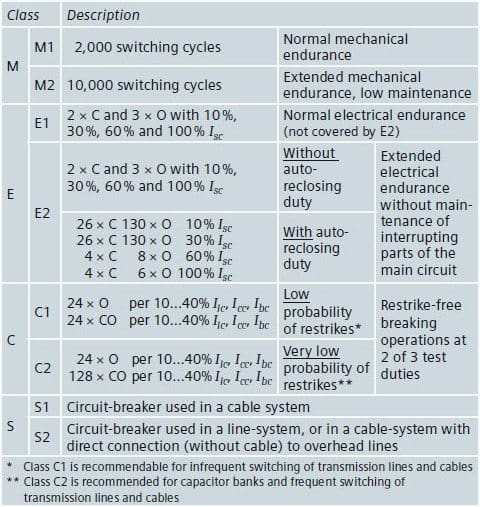

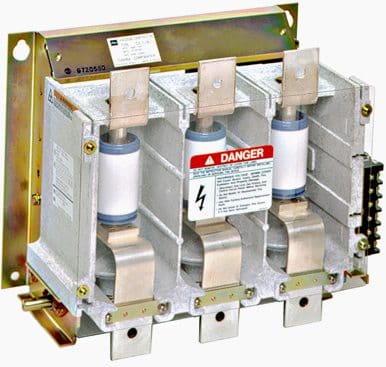

Circuit breakers

Whereas the number of mechanical operating cycles is specifically stated in the M classes, the circuit breaker standard IEC 62271-100/VDE 0671-100 does not define the electrical endurance of the E classes by specific numbers of operating cycles; the standard remains very vague on this.

Modern vacuum circuit breakers can generally make and break the rated normal current up to the number of mechanical operating cycles.

The switching rate is not a determining selection criterion, because circuit breakers are always used where short – circuit breaking capacity is required to protect equipment.

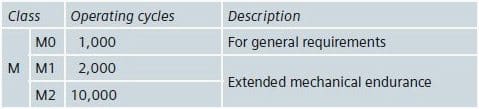

Disconnectors

Disconnectors do not have any switching capacity (switches for limited applications must only control some of the switching duties of a general-purpose switch). Switches for special applications are provided for switching duties such as switching of single capacitor banks, switching of ring circuits formed by transformers connected in parallel, or switching of motors in normal and locked condition.

Therefore, classes are only specified for the number of mechanical operating cycles.

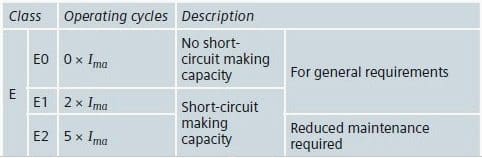

Earthing switches

With earthing switches, the E classes designate the short circuit making capacity (earthing on applied voltage). E0 corresponds to a normal earthing switch; switches of the E1 and E2 classes are also called make-proof or high-speed earthing switches.

The standard does not specify how often an earthing switch can be actuated purely mechanically; there are no M classes for these switches.

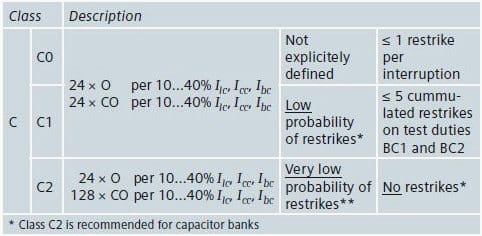

Contactors

The standard has not specified any endurance classes for conductors yet. Commonly used conductors today have a mechanical and electrical endurance in the range of 250,000 to 1,000,000 operating cycles.

They are used wherever switching operations are performed very frequently, e.g., more than once per hour.

References: SIEMENS Power Engineerind Guide – ‘Switchgear and Substations’

Thanks

is it real that endurance class E 2 is notpossible for circuit breakers above 52 kV

Hi, Is there any calculations to show if a CB is rated for E1,E2 or E3, what is the number of operations that the CB can clear on rated current(100%load)?

This is an excellent site giving ample details about power

Hi need to know what is the procedure to do high voltage test at 52kV DC between the phases

And what is the standard for the same