Introduction to ESD

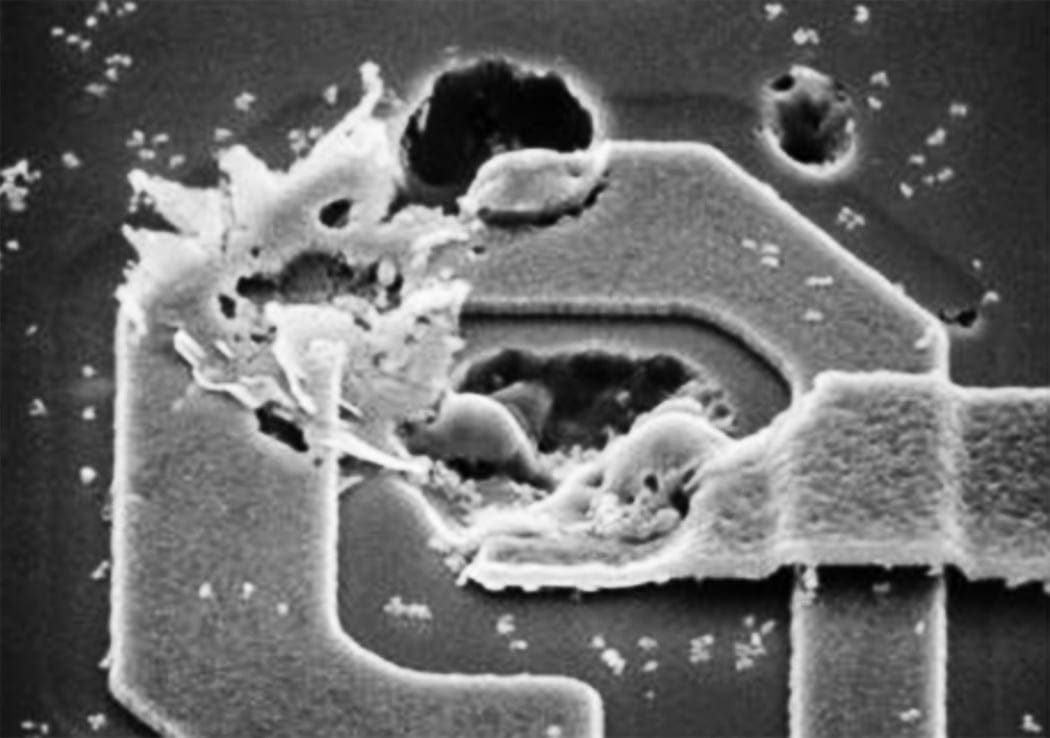

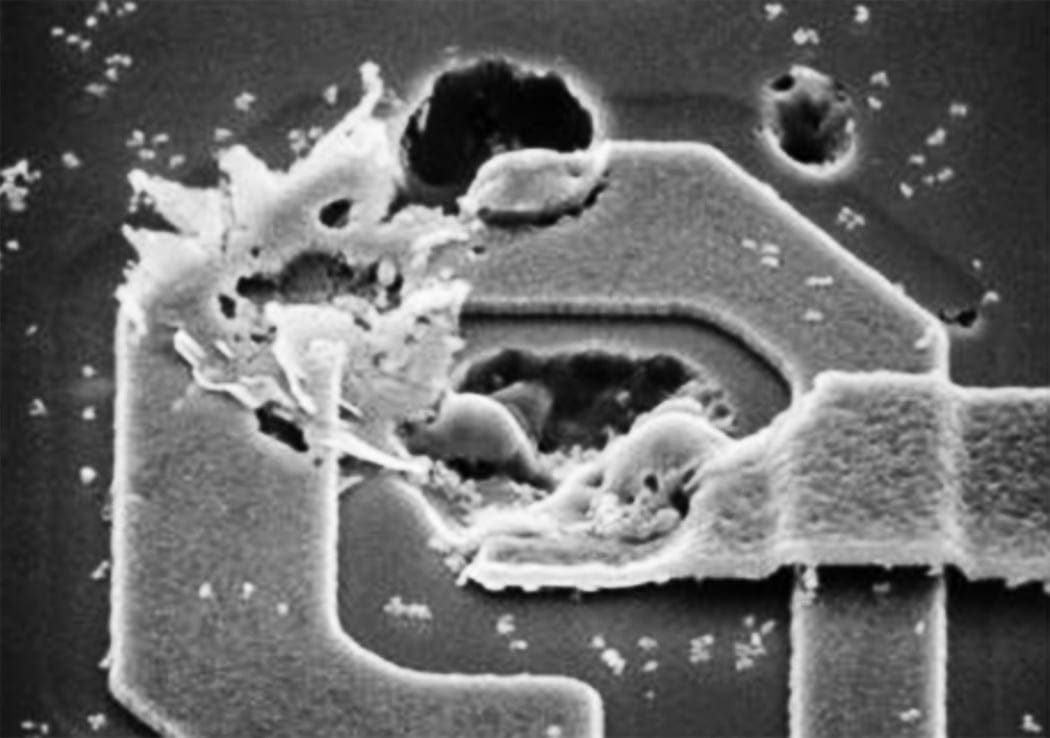

Let’s start with basics you probably already know, but nevertheless. It’s important to explain the basics first. Electrostatic Discharge (or ESD) refers to the transfer of electrostatic charge between bodies at varied voltages that is caused by direct contact or induced by an electrostatic field.

In summary, ESD damage occurs due to the following:

- Direct electrostatic discharge to the device

- Electrostatic discharge from the device

- Field-induced discharges

ESD damage can be unknowingly caused when inspecting, sorting, or installing the ESD-sensitive devices.

So what is the best practice?

The following best practices are recommended to prevent ESD damage:

#1 – Permanent / metallic wrist straps

Use permanent or metallic wrist straps instead of disposable ones as metallic wrist straps have better connectivity to the skin of the operator, and are less prone to failure when compared to disposable wrist straps, which are made of inexpensive and not very resistant material.

Because of this, the grounding cable or strip in disposable wrist straps can easily break, making the wrist strap totally ineffective.

Since permanent (metallic) wrist straps are very reasonably priced (usually a few US dollars), the usage of disposable wrist straps is not worth the risk.

#2 – ESD shoes

In all the installation sites that have conductive floors (tested according to the ANSI 20.20 standard), encourage wearing ESD shoes that have metallic elements, so that the static electricity gets discharged when the shoes come in contact with the ESD flooring.

Facilities with ESD flooring should test the flooring periodically to ensure that it maintains conductivity. However, be cautious during floor maintenance as floor waxes can reduce conductivity and create a level of insulation that prevents the effective dissipation of electrostatic charge.

ESD testing station

When implementing ESD flooring and ESD shoes, the facility should also have an ESD testing station to permit users to test their shoes to ensure that they maintain good conductivity throughout the lifetime of the shoes.

#3 – ESD mat

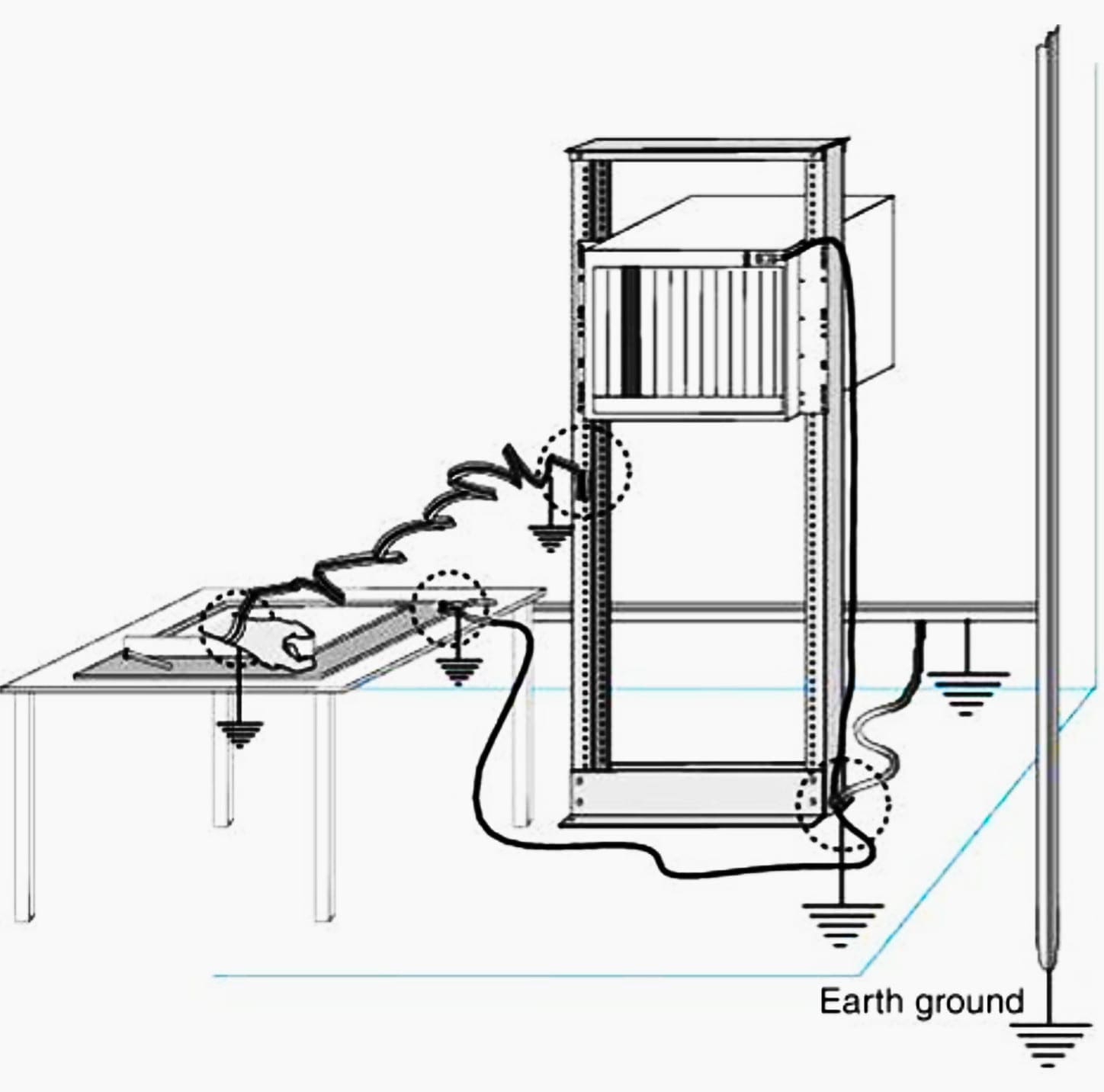

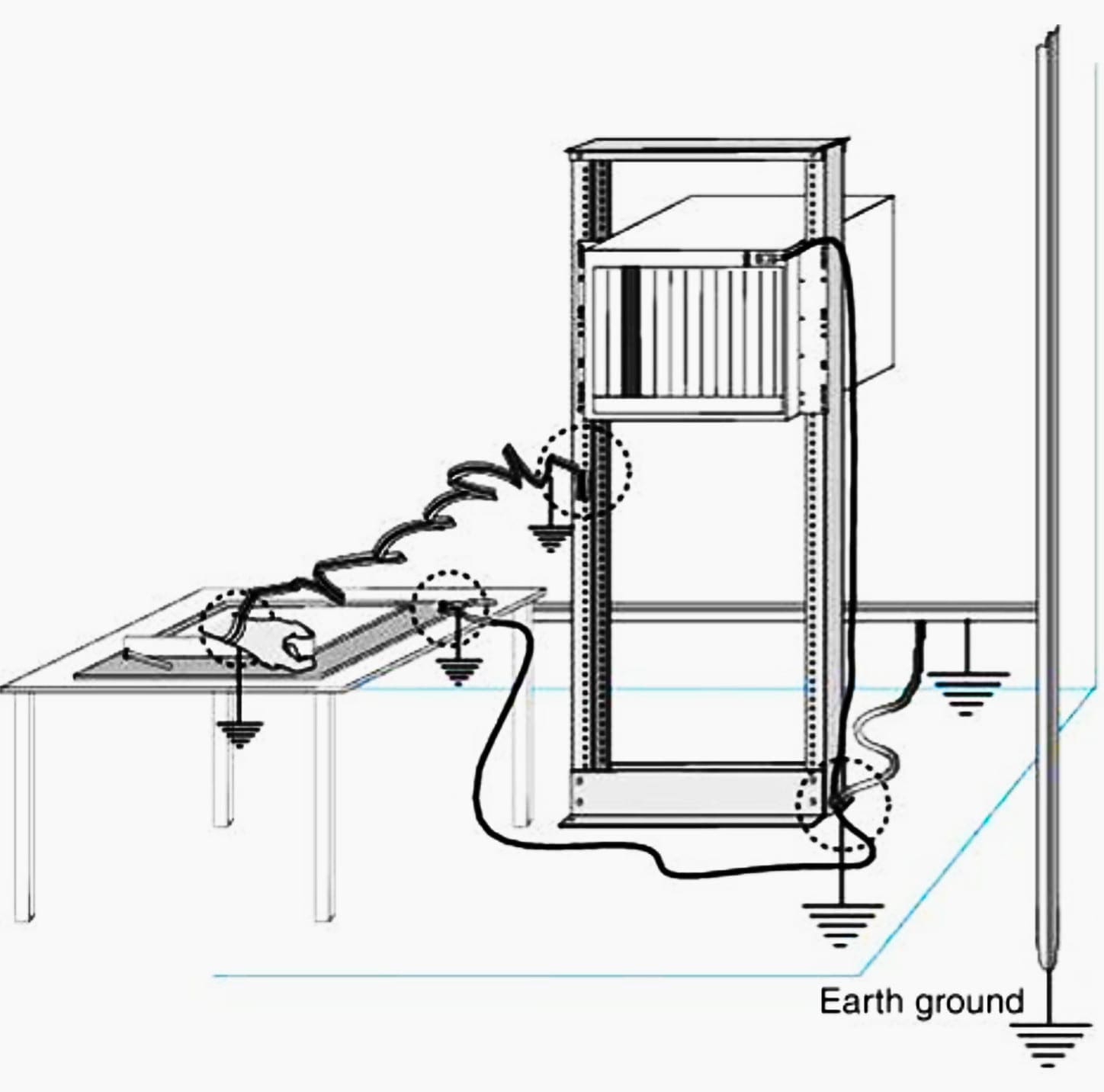

Use an ESD mat (see Figure 3) that is grounded to the rack when performing a card swap. In fact, if it is not possible to immediately store the replaced or damaged cards in an anti-static bag, the ESD mat offers a surface to temporarily keep the electronic equipment and prevent ESD damage.

Figure 4 outlines how to ground the mat to the same potential as the chassis and the rack.

Preventing ESD damage during card installation and replacement:

#4 – Test wrist strap resistance

Each time before using the wrist strap (permanent or disposable), test it using a multimeter to ensure that the resistance is less than 1 Mohm. This should be performed in addition to the periodic test of the ESD protective devices in accordance with the maintenance program of the customer or partner.

#5 – ESD protected areas procedure

If the installation site has ESD-protected areas, perform the following:

- Post appropriate signage indicating the ESD-protected area, so that it is clearly visible to the people entering the area.

- Allow only those who have completed the appropriate ESD training into the protected areas. The content of the training material should follow the ANSI 20.20 certification standard.

- Deionize or use other discharge-mitigating techniques in the workstations to neutralize eventual electrostatic charges.

See below descriptions of each of the points shown in Figure 5:

- Groundable wheels

- Groundable surface

- Wrist band and footwear tester

- Footwear footplate

- Wrist band and grounding cord

- Grounding cord

- Ground

- Earth Bounding Point (EBP)

- Groundable point of trolley

- Toe and heel strap (footwear)

- Deionizer

- Dissipative surfaces

- Seating with groundable feet and pads

- Floor

- Garments

- Shelving with grounded surfaces

- Groundable racking

- ESD Protective Area (EPA) sign

- Machine

Frequently missed requirements in the field

The following are examples of requirements that are frequently missed in the field:

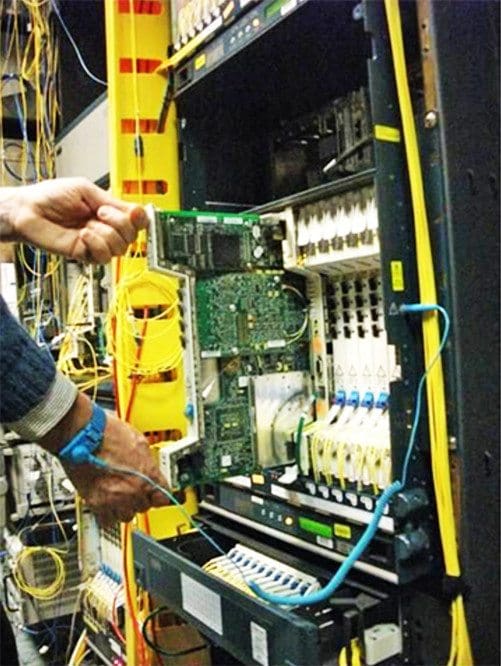

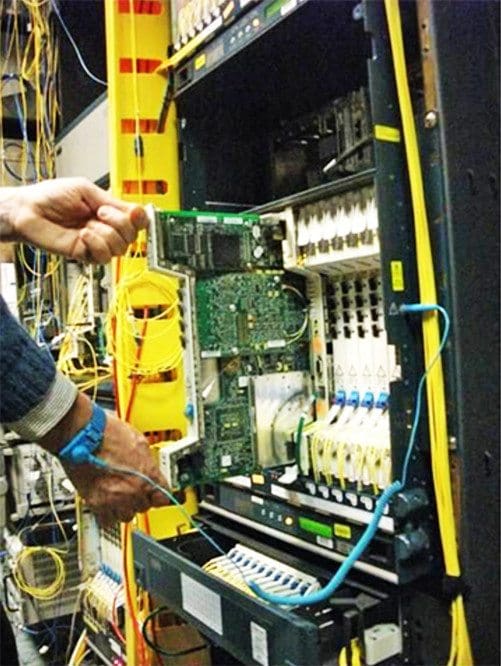

Example #1 Always use an ESD wrist strap to prevent the damage from ESD between your body and sensitive electronic components during the installation of electronic devices.

Example #2 Ensure that the wrist strap is properly connected to the equipment. Most Cisco equipment has an appropriate hole to plug in the wrist strap and ensure good connectivity to the device and ultimately the ground (Figure 7).

In case of limitations such as the length of the wrist strap preventing the connection to the proper connecting point on the device, ensure that the wrist strap is connected to an unpainted surface or a ground wiring that mounts on the device or a rack.

Avoid connecting the wrist strap to painted surfaces (see Figure 9 and Figure 10).

If wrist strap is not available, touch a conductive part of the data networking equipment:

Temporary wrist strap connected to a non-conductive part of the rack:

Or a Non-conductive paint on a rack:

Example #3 During installation or removal, handle electronic equipment using the available handles or edges. Even if you are using an ESD wrist strap, it is important to avoid touching the electronic components to prevent mechanical damage or depositing oil that is present on your hands.

Example #4 When replacing a failed card, place it component side up on an antistatic surface (ESD mat) or in a static-shielding bag.

Example #5 Insert the card into the chassis completely until you can tighten the captive screws and/or levers to ensure a good connection between the backplane of the chassis and card. This is necessary for proper grounding and ESD protection of the cards.

Reference // Guidelines and best practices for the installation and maintenance of data networking equipment by CISCO

I am really happy to learn more through the article.

I often have ESD choc when touching boom gate button…and ask myself what to do.Have any advise to help to find how this can be avoid as it is sometime very strong. I am not working in a network environment.