Fully digital substation

Developments in communication have done much to realize the digital substation, but to realize a full digital substation it is necessary to have everything in digital form. Whilst much substation protection, control, and automation technology has always been digital (trip signals, interlocking signals, etc.), the principal power system inputs of voltage and current have traditionally been presented in analogue form.

It has been traditional to present scaled versions of power system currents and voltages to measuring devices, protective relays etc. Scaled versions can easily be produced using conventional electrical transformers, although capacitor dividers may be additionally employed for transforming very high voltages.

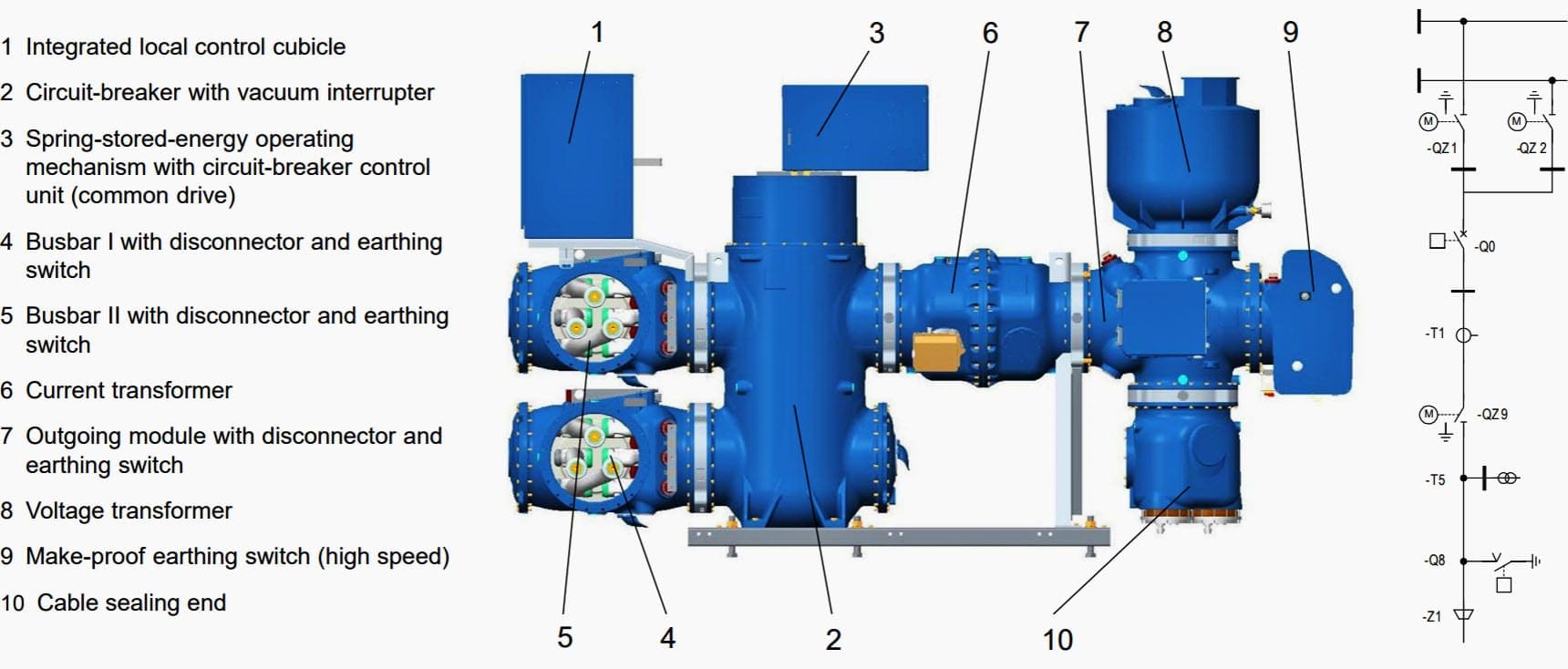

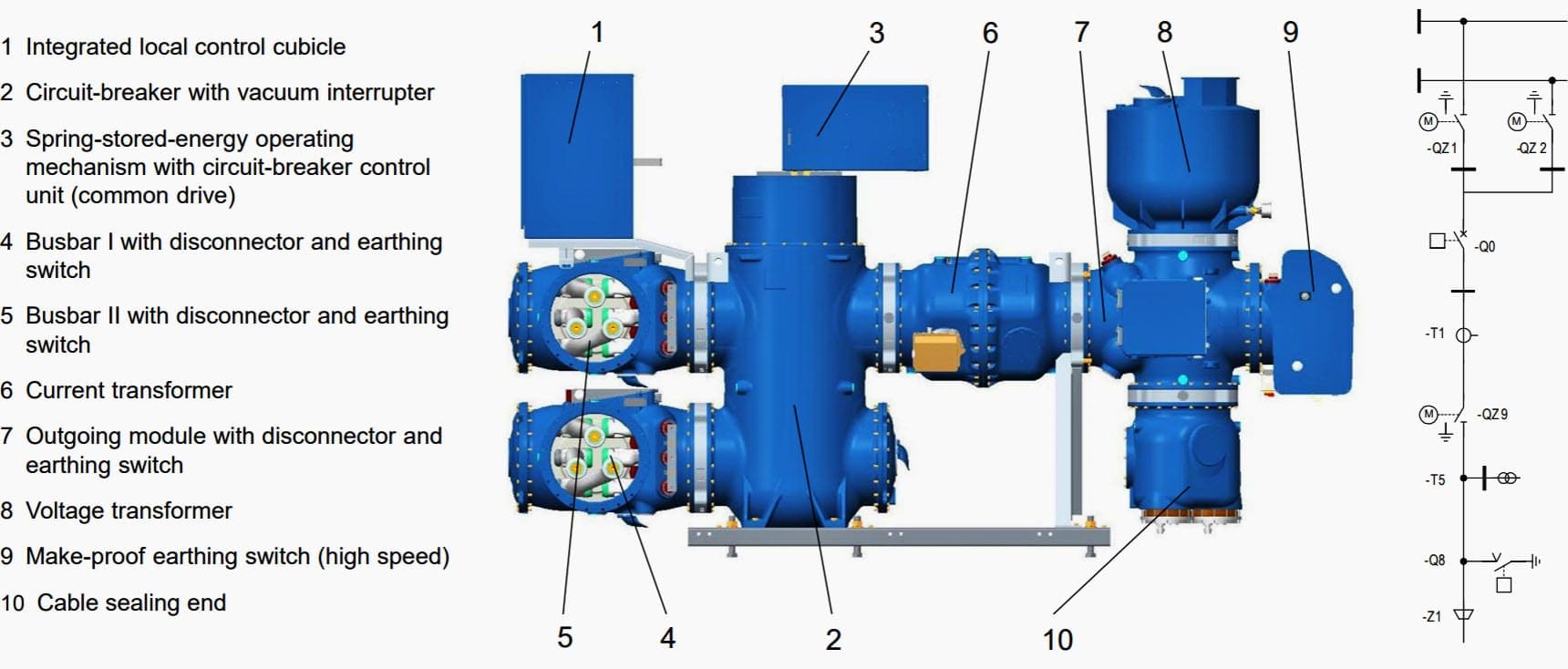

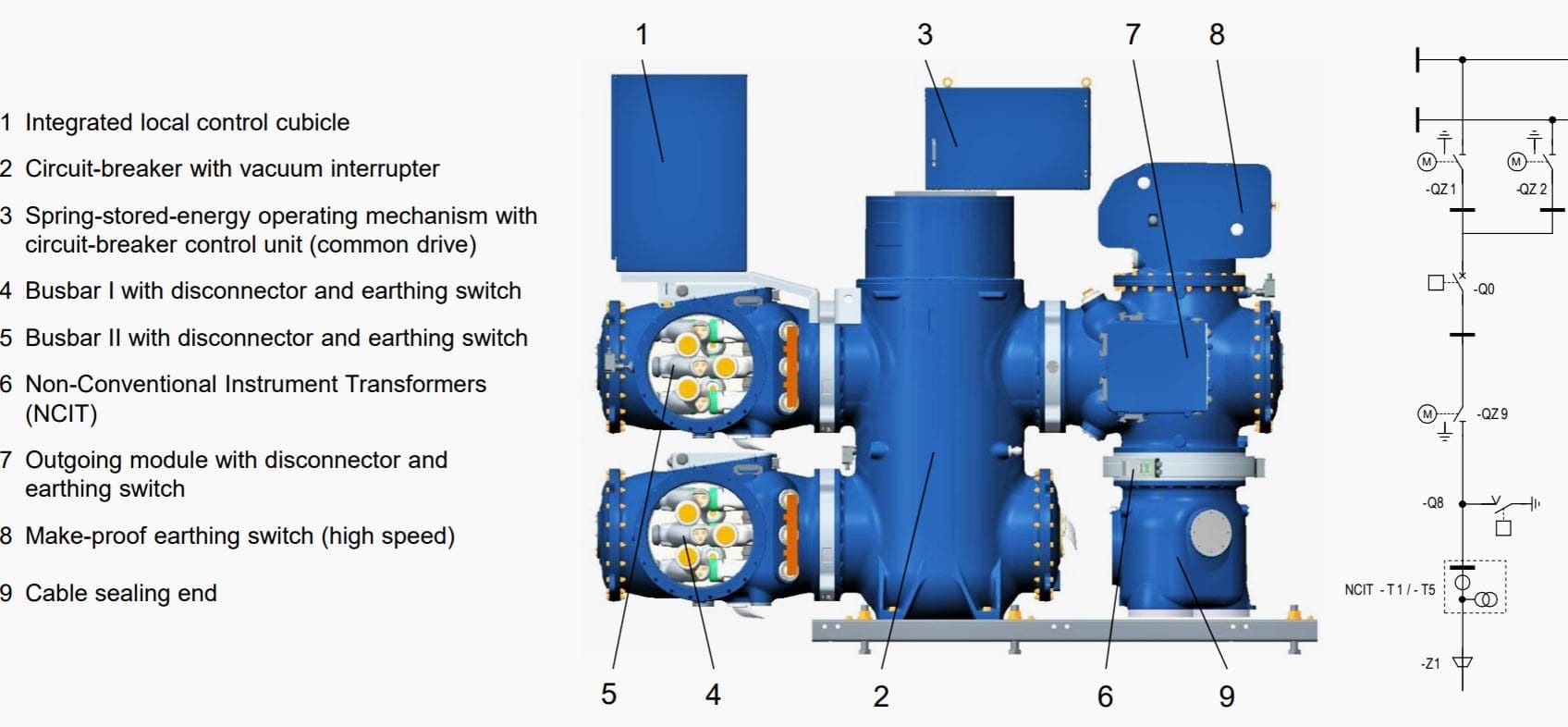

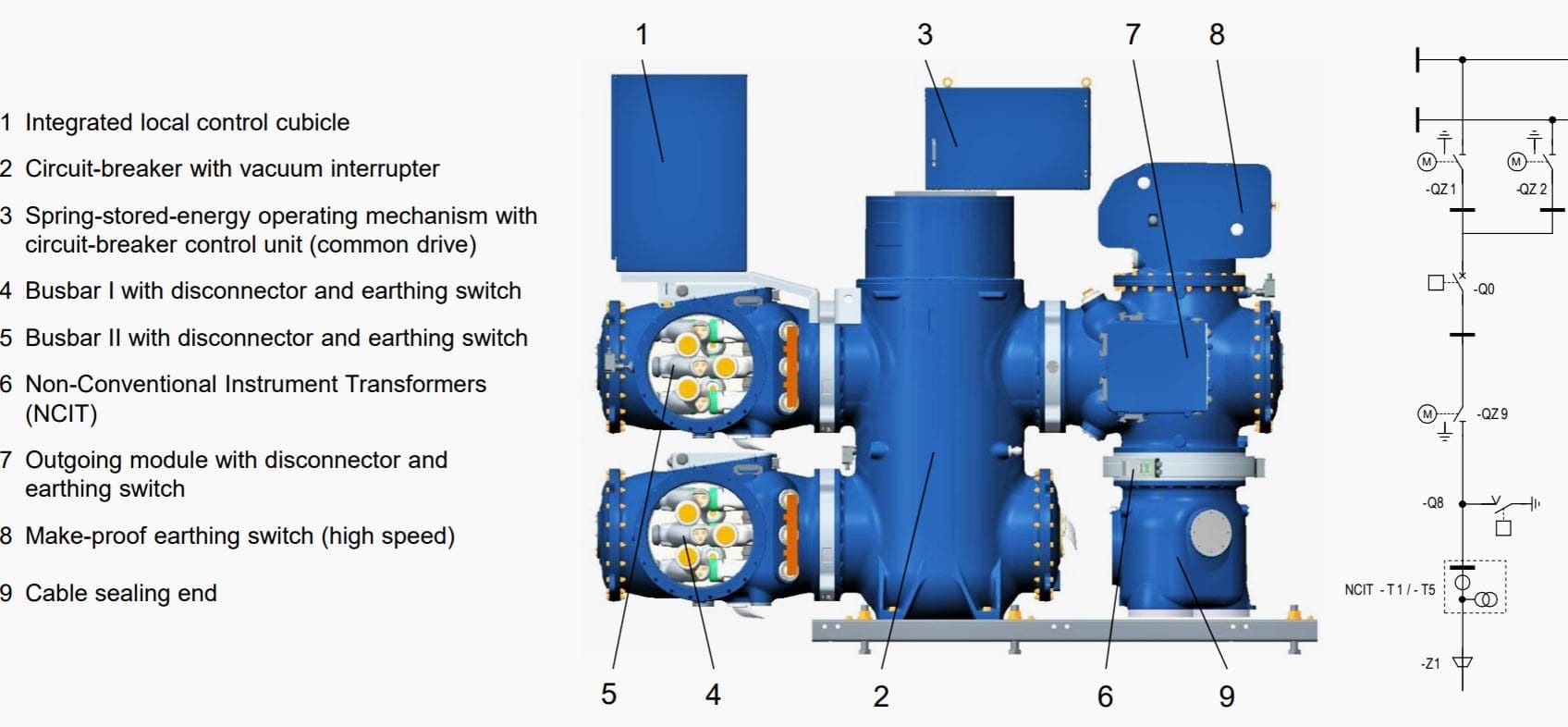

Let’s continue the discussion by following the topics which are suited to GIS substations:

1. Conventional and Non-Conventional Instrument Transformers (NCIT)

Conventional transformers based on iron cores introduce measurement errors. Due to the wide dynamic range of current signals on power systems, current transformers for protection need large cores to avoid saturation under fault conditions.

Due to the nature of the magnetic core material, however, these large cores produce significant errors at nominal current, which renders them impractical for metering purposes.

Therefore metering-class transformers need to be introduced resulting in increasing costs.

Conventional wired 1A/5A current transformers (CT) circuits have thermal overload constraints and pose increasing burdens on the core as cross-site wire run lengths increase.

This can degrade protection performance, potentially leading to the need to duplicate CTs. Conventional voltage transformer (VT) circuits may experience ferro-resonance phenomena, with thermal overstress resulting. Capacitor voltage transformers (CVT) can produce high frequency interference signals.

Techniques that do not require the iron core of conventional transducers can overcome the limitations. The solutions use different sensor technologies such as optical and Rogowski coils. In practical implementations, the techniques require sophisticated solutions employing digital signal processors and microprocessors in numerical products.

This presentation of analogue power system quantities in the form of standardized digital communication signals is the final element in realizing the digital substation.

Solutions providing signal transformation based on technology other than wound transformers are often referred to as non-conventional instrument transformers (NCIT), and the devices that provide the standardized digital communication equivalents of the power system signals are referred to as

merging units.

NCIT technologies may be based on optical techniques, or Rogowski coils, and overcome the limitation of iron-cored transformers by delivering:

- Single devices providing measurement class accuracy with dynamic ranges also capable of faithfully reproducing fault currents.

- Reliable, repeatable accuracy.

- High measurement bandwidth for rated frequency, harmonics, and sub-harmonics.

- Low electrical stress insulation – no premature ageing, moisture ingress, or risk of explosion.

An NCIT device based on Rogowski coil technology is shown in Figure 3 below.

Some pilot applications using NCIT (Non Conventional Instrument Transformers) have been implemented in France and UK on actual 245 and 420 kV GIS. These field trial installations have confirmed the performances of these modern sensors, as well as the robustness of a comprehensive Protection and Metering system governed by the former applications of the IEC 61850.

Making use of Protection relays from different vendors, these pilots also proved the perspectives of interoperability, absolutely mandatory for the End users.

Despite the maturity of these technologies, the limitation of their utilization is a reality and some reasons can be reminded to explain that.