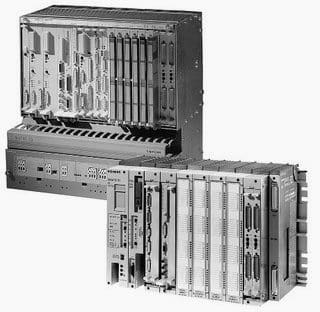

Modular Digital Controller (MODICON)

PLCs (Programmable Logic Controllers) were first introduced in the 1960’s. The primary reason for designing such a device was eliminating the large cost involved in replacing the complicated relay based machine control systems.

Bedford Associates (Bedford, MA) proposed something called a Modular Digital Controller (MODICON) to a major US car manufacturer. The MODICON 084 brought the world’s first PLC into commercial production.

When production requirements changed so did the control system. This becomes very expensive when the change is frequent. Since relays are mechanical devices they also have a limited lifetime because of the multitude of moving parts. This also required strict adhesion to maintenance schedules.

These relays would be individually wired together in a manner that would yield the desired outcome. The problems for maintenance and installation were horrendous. These new controllers also had to be easily programmed by maintenance and plant engineers.

The lifetime had to be long and programming changes easily performed.

They also had to survive the harsh industrial environment. The answers were to use a programming technique most people were already familiar with and replace mechanical parts with solid-state ones which have no moving parts.

They could also now be used to send and receive varying voltages to allow them to use analog signals, meaning that they were now applicable to many more control systems in the world. Unfortunately, the lack of standardization coupled with continually changing technology has made PLC communications a nightmare of incompatible protocols and physical networks.

The 1980’s saw an attempt to standardize communications with General Motor’s manufacturing automation protocol (MAP). It was also a time for reducing the size of the PLC and making them software programmable through symbolic programming on personal computers instead of dedicated programming terminals or handheld

programmers.

The 1990’s saw a gradual reduction in the introduction of new protocols, and the modernization of the physical layers of some of the more popular protocols that survived the 1980’s. PLCs can now be programmable in function block diagrams, instruction lists, C and structured text all at the same time. PC’s are also being used to replace PLCs in some applications.

The original company who commissioned the MODICON 084 has now switched to a PC based control system.

PLC Training – Introduction to PLC Ladder Logic (VIDEO)

Cant see this video? Click here to watch it on Youtube.

SOURCE: Programmable Logic Controllers and Ladder Logic